When an offshore project manager receives a quote stating “12-14 weeks delivery,” the response is often the same: “Can’t you make it faster?”

The truth is, metal forging isn’t like ordering off-the-shelf parts. Every custom forging follows a precise sequence of steps, each with its own timeline, its own critical checkpoints, and its own potential delays.

After 30 years in the forging industry, we’ve guided hundreds of offshore equipment projects from initial inquiry to final delivery. This article breaks down the real timeline, week by week, so you know exactly what happens between your drawing and your delivery.

Your timeline doesn’t start when the forge fires up. It starts the moment you place your order.

What happens:

Typical duration: 1-2 weeks for standard grades, 3-4 weeks for exotic alloys

Reality check: If you need duplex stainless steel with NORSOK certification, your material might come from a specific mill in Italy or Germany. That mill might have a 6-week lead time before they even cast your ingot.

Many projects get delayed here because procurement waited too long to release the purchase order. The forge can’t start without verified material. No amount of expediting changes steel mill schedules.

Once material arrives at the forge, the real metal forging process begins.

What happens:

Typical duration: 3-5 days depending on size

Why it takes time: A large ring blank weighing several tons can’t be rushed to temperature. Heat it too fast and you create thermal stress. The material needs hours, sometimes a full day, to reach uniform temperature throughout its mass.

For a 4-meter diameter ring weighing 8-10 tons, physics doesn’t negotiate.

This is where the magic happens, and where experience separates good forgings from scrap.

What happens:

Typical duration: 1-3 weeks depending on complexity

The variables: A simple carbon steel shaft might be forged in two days. A complex super duplex ring with tight tolerances might require multiple heating cycles and careful monitoring over two weeks.

Ring rolling is particularly time-sensitive. Each pass must be carefully controlled. Too much reduction per pass creates internal stress. Too little means more reheats and longer production time.

We’ve seen projects where a client insisted on rushing this stage. The result? Internal cracking discovered during ultrasonic testing, requiring the entire piece to be scrapped and restarted. That “time saved” cost six weeks.

Here’s where many people underestimate the timeline. Heat treatment isn’t optional. It’s what gives your forging its mechanical properties.

What happens:

Typical duration: 1-2 weeks

Why it’s critical: A large duplex stainless ring must be heated to 1050-1100°C, held at temperature for hours (time depends on section thickness), then quenched rapidly to prevent harmful phase precipitation.

After quenching, the part is still under internal stress. It needs time to stabilize before machining. Rush this, and your carefully forged component will warp during machining, ruining tolerances you paid premium prices to achieve.

For offshore equipment operating subsea or in pressure vessels, proper heat treatment ensures the right microstructure. This directly affects corrosion resistance, toughness at low temperatures, and resistance to stress corrosion cracking.

Before any machining begins, the forging must prove it meets specifications.

What happens:

Typical duration: 1-2 weeks

The inspection challenge: For NORSOK projects requiring 3.2 certificates, you need an independent inspector present during testing. Their schedule becomes your schedule. If the inspector isn’t available for two weeks, you wait two weeks.

We coordinate inspector schedules early in the project. This single action has saved clients weeks of delay.

What if testing fails? If ultrasonic testing reveals an internal defect, the part might need additional heat treatment or, in worst cases, must be scrapped and restarted. This is why reputable forges have quality control throughout the process, not just at the end.

Now your rough forging becomes a precision component.

What happens:

Typical duration: 2-4 weeks depending on complexity

Machining realities: A compact flange with multiple seal grooves, bolt holes, and tight flatness tolerances can take 3-4 weeks on a CNC machine. You’re removing material to tolerances of 0.1mm or tighter on parts weighing tons.

For custom forgings with complex geometries, machining often takes longer than the forging itself.

The component is made, but it’s not ready to ship.

What happens:

Typical duration: 1-2 weeks

Documentation matters: Your final package includes material certificates, test reports, dimensional inspection reports, weld procedures (if any), and traceability documentation. For offshore projects, this paperwork is as important as the component itself.

Missing or incomplete documentation has held shipments at customs for weeks. We prepare documentation packages throughout the project, not as a last-minute scramble.

Beyond the standard timeline, several factors can extend delivery:

Material availability: Exotic alloys (Inconel, titanium, 6Mo stainless) can add 4-8 weeks to material procurement alone.

Size extremes: Components over 6 meters diameter require specialized equipment. Only a handful of forges worldwide can handle them, and they’re booked months in advance.

Specification complexity: Sour service requirements (H₂S resistance) add testing. Low-temperature service adds Charpy impact testing. Each additional requirement adds time.

Rework and repairs: Even at the best forges, approximately 5-10% of forgings require some level of rework. Build this into your planning.

Forge capacity: During high oil prices, offshore forges are booked solid. Your 12-week component might face a 4-week queue just to start.

Yes, expediting is possible, but only in specific circumstances:

What can be expedited:

What cannot be expedited:

We’ve successfully cut timelines by 20-30% through careful planning and premium scheduling. But claims of “50% faster” usually mean corners are being cut somewhere.

When clients absolutely need faster delivery, it’s possible, but expensive:

A €50,000 forging can easily become €75,000 when fully expedited. Sometimes this makes sense. Usually, better planning is cheaper.

Reputable suppliers communicate these issues early. If you’re getting vague answers or consistent one-week delays, your project is in trouble.

For a typical offshore equipment forging (duplex stainless ring, 3-4 meter diameter, machined):

For exotic materials, extreme sizes, or complex geometries, add 4-8 weeks to each category.

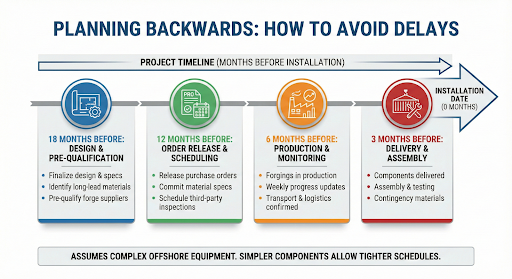

Smart project managers plan backwards from installation date:

18 months before installation:

12 months before installation:

6 months before installation:

3 months before installation:

This timeline assumes complex offshore equipment like manifolds, swivel stacks, or subsea connectors. Simpler components allow tighter schedules.

Understanding the real timeline of metal forging production helps you:

When a supplier quotes “8 weeks for a complex duplex manifold,” they’re either cutting corners or don’t understand their own process. When they quote “16-18 weeks with these specifications,” they’re being honest about what quality takes.

We’ve spent three decades learning these timelines, and building relationships with forges that deliver consistently.

Our value isn’t just knowing where to buy forgings. It’s knowing:

We plan your timeline backwards from your need-by date, build in appropriate contingency, and monitor every step. When issues arise, and they sometimes do, we have the relationships and experience to find solutions.

Your project schedule is too important to guess. Work with people who know the real timeline, and have 30 years of delivered projects to prove it.

Need custom forgings with realistic timelines? Contact ProSteel Supply. We’ll give you the truth about what’s possible, and deliver on what we promise.

Download our whitepaper and gain practical insights into materials, quality, and supply reliability.