“This flange cracked after six months. It was supposed to last 25 years.”

The project engineer held up the inspection report. A 2-meter duplex flange. €45,000. Failed on an offshore wind platform 80 kilometers from shore.

The cause? Not the design. Not the installation. The material couldn’t handle the environment.

Welcome to offshore wind. Where forgings face conditions more severe than oil platforms, chemical plants, or subsea installations. Where 25-year service life isn’t optional. Where failure means €10 million in vessel costs to replace a single component.

After three decades supplying forgings to offshore projects, we’ve learned one truth: offshore wind doesn’t just need good forgings. It needs forgings designed for the harshest environment on earth.

This article explains why offshore conditions destroy normal forgings, what offshore engineering demands, and how component testing and fatigue resistance separate components that last from components that fail.

Offshore wind platforms combine every challenge that destroys metal.

Saltwater exposure. Temperature cycles. Mechanical stress. UV radiation. Humidity. Sand abrasion. All simultaneously. For 25 years. With minimal maintenance access.

No other environment is this aggressive.

Seawater is the most corrosive environment forgings face. High chloride content. Dissolved oxygen. Biological activity. Temperature variation.

Standard carbon steel rusts through in months without protection. Even stainless steel 316L develops pitting and crevice corrosion in warm seawater.

Offshore wind forgings must resist this for decades.

Wind turbines create constant cyclic loading. Blades rotate 10-15 times per minute. Tower sways in wind and waves. Foundation experiences wave impacts.

This creates millions of stress cycles over a turbine’s lifetime. Metal fatigues under repeated loading. Cracks initiate and grow. Components fail.

Offshore wind forgings must maintain fatigue resistance through 100+ million cycles.

Offshore platforms experience extreme temperature swings. Summer sun heats exposed metal to 50°C. Winter storms drop temperatures to -20°C or lower.

These cycles create thermal stress. Materials expand and contract. Joints loosen. Seals fail. Corrosion accelerates.

Offshore wind forgings must perform across 70°C temperature range.

Replacing a failed forging offshore requires specialized vessels at €800,000+ per day. Weather windows are limited. Turbine must be shut down. Revenue is lost.

A €50,000 forging that fails costs €5-10 million in replacement logistics. Plus project reputation damage. Plus operator confidence loss.

This makes reliability non-negotiable.

Standard industrial forgings aren’t designed for offshore conditions. They fail in predictable ways.

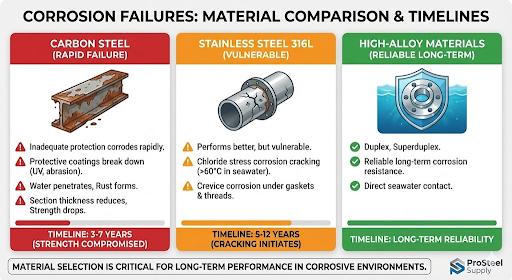

Carbon steel without adequate protection corrodes rapidly. Protective coatings break down under UV and abrasion. Water penetrates. Rust forms. Section thickness reduces. Strength drops below design limits.

Timeline: 3-7 years before strength is compromised.

Stainless steel 316L performs better but still vulnerable. Chloride stress corrosion cracking occurs above 60°C in seawater. Crevice corrosion develops under gaskets and in threaded connections.

Timeline: 5-12 years before cracking initiates.

Only high-alloy materials (duplex, superduplex) provide reliable long-term corrosion resistance in direct seawater contact.

Forgings not designed for cyclic loading develop fatigue cracks. These typically initiate at:

Once initiated, fatigue cracks grow with each load cycle. Eventually the remaining material can’t carry the load. Sudden failure occurs.

Timeline: Highly variable. Can be 2 years or 20 years depending on stress levels and material quality.

In sour service (H₂S environments) or cathodic protection systems, hydrogen atoms can diffuse into steel. This makes the material brittle. Impact resistance drops. Cracks propagate easily.

High-strength steels are particularly susceptible. Materials above 22 HRC hardness are at risk in offshore environments.

Timeline: Can occur within months if conditions are severe.

Designing forgings for offshore wind requires different approaches than standard industrial applications.

Material choice determines corrosion resistance and fatigue performance.

For direct seawater contact:

For atmospheric exposure with water spray:

Duplex stainless minimum. Carbon steel with high-quality coating systems acceptable in some cases but requires maintenance.

Material selection isn’t about cheapest option. It’s about what survives 25 years.

Offshore forgings must be designed to avoid fatigue failure. This requires:

This adds design and manufacturing cost. It prevents catastrophic failures.

Every offshore forging must be fully traceable. Material heat numbers. Chemical composition. Mechanical properties. Heat treatment records. Inspection results.

This documentation proves the forging meets specifications. It provides basis for lifetime extension decisions. It supports root cause analysis if failures occur.

Offshore engineering demands documentation depth that onshore projects often skip.

Offshore forgings undergo extensive testing before they’re approved for use. This testing validates that material and design meet requirements.

Standard tests include:

For offshore forgings, these tests are performed at multiple locations. Surface and core must both meet specifications.

Standard corrosion tests for offshore materials:

These tests take weeks to complete. They’re non-negotiable for critical offshore components.

Fatigue testing subjects material to cyclic loading and measures cycles to failure. This validates fatigue resistance predictions.

For offshore forgings:

Fatigue testing is expensive and time-consuming. A single test program costs €50,000-150,000 and takes 3-6 months.

But it’s the only way to prove a design will survive 25 years of cyclic loading in corrosive environment.

Every production forging undergoes non-destructive testing:

For offshore applications, acceptance criteria are stricter than standard industrial. Defects that would be acceptable onshore are rejected for offshore service.

Fatigue failures are insidious. The component looks fine during inspection. No visible damage. No measurable wear. Then it suddenly fractures.

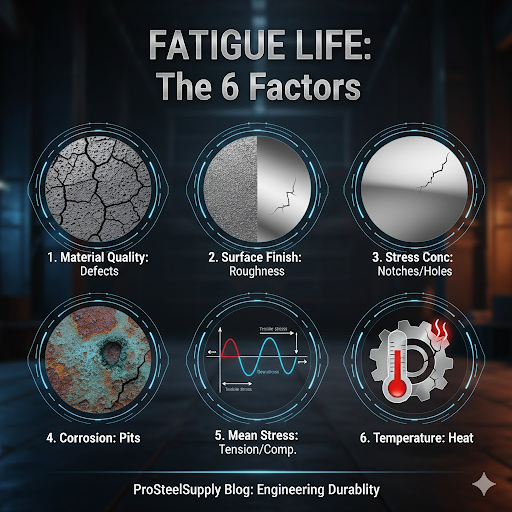

Metals fail under repeated loading at stress levels well below their ultimate strength. Each load cycle creates microscopic damage. This damage accumulates over millions of cycles until a crack forms.

The crack grows with each additional cycle. Eventually the remaining cross-section can’t carry the load. Sudden catastrophic failure occurs.

Fatigue is the leading cause of mechanical failure in offshore structures.

Designing for fatigue requires understanding all these factors and their interactions.

Every failure teaches lessons. Offshore wind has had its share.

North Sea wind farm. 8 MW turbines. Tower flanges developed cracks after 4 years operation.

Root cause: Material was specified as duplex but heat treatment was improper. Microstructure contained sigma phase precipitates. This reduced toughness and fatigue resistance.

Lesson: Heat treatment verification is critical. Metallographic examination should be mandatory for critical forgings.

Cost: €15 million in replacement flanges and vessel mobilization.

Baltic Sea installation. Anchor bolts connecting transition piece to foundation failed during storm.

Root cause: Bolts were high-strength steel with inadequate hydrogen embrittlement resistance. Cathodic protection system drove hydrogen into the material. Bolts became brittle and fractured.

Lesson: High-strength fasteners in seawater with cathodic protection require special material selection and testing.

Cost: €8 million in emergency repairs and lost generation.

UK wind farm. Flange connections under thermal insulation showed severe corrosion after 6 years.

Root cause: Insulation trapped moisture against steel surface. Standard carbon steel coating system was inadequate for constant wet conditions.

Lesson: Areas under insulation need same corrosion protection as direct seawater exposure. Duplex or high-quality coating systems required.

Cost: €12 million in platform refurbishment.

After 30 years supplying forgings to offshore projects, we understand what offshore wind demands.

Material expertise:

We specify materials that survive offshore conditions. Duplex and superduplex for seawater contact. Proper heat treatment protocols. Hydrogen embrittlement prevention for high-strength applications.

Our forge network includes only suppliers with proven offshore track records.

Design support:

We review designs for fatigue resistance. We identify stress concentrations. We recommend geometry modifications. We specify surface finishes that extend component life.

This upfront engineering prevents expensive failures years later.

Testing coordination:

We coordinate all required component testing. Mechanical properties. Corrosion resistance. Fatigue performance. Non-destructive examination.

We work with accredited test labs and class society witnesses. Documentation meets offshore certification requirements.

Quality assurance:

Every forging is traceable from steel mill to installation. Heat treatment is verified. Mechanical properties confirmed. Surface finish documented.

We don’t ship forgings hoping they meet spec. We prove they meet spec.

Offshore wind platforms face the most aggressive environment forgings encounter. Seawater corrosion. Cyclic fatigue. Temperature extremes. Limited maintenance access.

Normal industrial forgings fail in this environment. Proper offshore engineering, rigorous component testing, and proven fatigue resistance are mandatory.

Yes, offshore-grade forgings cost more than industrial-grade. Yes, testing adds time and expense. Yes, documentation requirements are extensive.

But offshore failures cost orders of magnitude more. A €50,000 forging that fails creates €5-10 million in replacement costs.

The forgings that survive 25 years offshore aren’t the cheapest forgings. They’re the forgings designed, tested, and manufactured specifically for offshore conditions.

Need forgings for offshore wind projects? ProSteel Supply coordinates offshore forging supply daily. We’ll specify materials that survive. We’ll coordinate testing that proves performance. We’ll deliver forgings that last 25 years.

Contact us for offshore forging guidance. Because in offshore wind, the forgings that fail cost more than the forgings that work.

Download our whitepaper and gain practical insights into materials, quality, and supply reliability.