In critical industrial applications, component failure isn’t just inconvenient – it’s catastrophic. The open die forging process delivers the exceptional material properties your most challenging projects demand.

When component integrity directly impacts safety, performance, and project timelines, the superior grain structure of open die forgings becomes non-negotiable.

The nightmare scenario: Your critical open die forgings fail during operation, or worse – fail inspection after weeks of production delay, derailing your entire project timeline and budget.

We’ve witnessed the recurring fears that procurement professionals face:

Not knowing if your supplier truly understands how forging parameters affect final material properties

Navigating the complex world of material standards and heat treatment requirements without specialized technical support

Receiving promises of "10 weeks delivery" only to discover halfway through that it was never realistic

Discovering too late that inadequate forging processes have introduced internal defects that compromise performance

Managing multiple vendors across forging, heat treatment, and machining with no single point of accountability

When your application requires specific mechanical properties, simply ordering to a standard grade isn’t enough. We ensure the forging process parameters are tailored to achieve your exact requirements.

Internal stresses in forged components can cause dimensional shifts during machining. Our expertise in heat treatment sequencing prevents these costly surprises.

Some dimensions simply cannot be achieved directly through open die forging. We identify these early and recommend the optimal combination of forging tolerances and subsequent machining.

Determining whether machining should occur before or after heat treatment can dramatically impact final component quality. Our process knowledge ensures the optimal manufacturing sequence.

While most steel trading companies merely trade steel, we’ve operated within a forge for 25 years.

Through our network of specialized open die forging companies, we deliver comprehensive solutions for your most demanding applications:

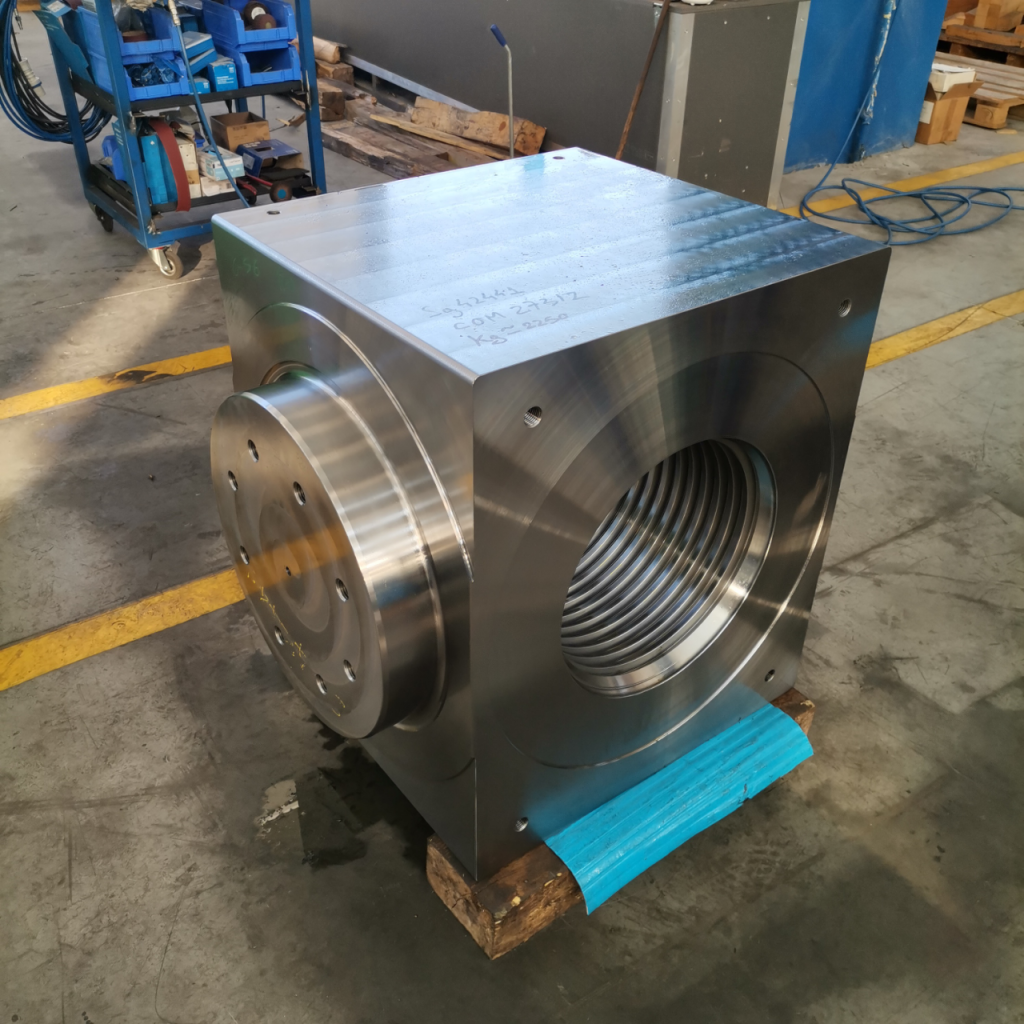

Precision-forged material in rectangular or cylindrical forms with optimized grain structure

Forged components with superior mechanical properties and continuous grain flow

Hollow components with exceptional circumferential strength

From raw forgings to heat-treated, tested, and fully machined components

Unlike casting or machining from plate, the open die forging process fundamentally transforms the metal’s internal structure:

This complex process requires extensive expertise to execute properly – expertise that directly translates into component performance and reliability.

Carefully chosen steel ingot with precise chemical composition

Controlled heating to 1000°C in specialized furnaces

Skillful compression under massive hydraulic presses (up to 16,000 tons)

Manipulating the material to optimize grain flow for maximum strength

Precise temperature reduction to develop specific material properties

Additional thermal processing to achieve final mechanical characteristics

Subsea components that operate reliably for 30+ years under extreme pressure.

From critical replacement parts to new installations meeting stringent standards.

Machine manufacturers and equipment producers who demand perfection.

When vessel standby costs run €100,000-800,000 daily, component failure isn’t acceptable.

Unlike ordinary steel traders, we bring forge-floor experience to every project:

With ProSteel Supply, you’re not just buying metal. You’re securing the expertise that ensures your components perform as intended, when intended.

Deep understanding of metallurgy, forging processes, and heat treatment

Structured monitoring with regular verification throughout production

Relationships with elite open die forging companies across Europe and Asia

Single point of responsibility from specification to delivery

Tailored approach to your unique application requirements

Unlike volume-focused open die forging companies who prioritize standardized high-volume orders, we value projects of all sizes:

Every forging receives the same meticulous attention, regardless of size or quantity.

Submit your inquiry today and discover how our specialized knowledge and extensive producer network can deliver the precise open die forged components your project demands.

Download our whitepaper and gain practical insights into materials, quality, and supply reliability.