When your forged components require precise dimensions, you face a critical decision: attempt machining yourself or entrust it to specialists. The wrong choice can turn a perfectly good forging into expensive scrap, while adding weeks to your project timeline.

Machining forged components requires careful coordination between forging, heat treatment, and machining operations. Poor sequencing can result in dimensional instability, warping, or components that can't achieve final specifications.

Many forged components require heat treatment after rough machining but before final finishing. Managing dimensional changes through this process requires specialized expertise that many machining facilities don't possess.

When you need precision machining for large or specialized forged components, finding facilities with appropriate equipment and availability can be challenging. Standard machine shops often can't accommodate the size or complexity of forged components.

Different applications require different levels of machining precision. Understanding where you can save costs through rough machining versus where final precision is essential requires deep knowledge of both machining capabilities and application requirements.

For clients with internal machining capabilities, we deliver forgings in their as-forged condition—cleaned of scale but unmachined. This option provides maximum material for your machining operations while maintaining the lowest cost.

Ideal for: Clients with specialized machining equipment or unique finishing requirements

We provide rough machining that removes excess material and brings components close to final dimensions, leaving sufficient material for your final finishing operations. This approach reduces your material costs and machining time while maintaining control over critical dimensions.

Ideal for: Clients who want to perform final machining in-house while reducing material waste and machining time

We deliver components machined to your exact specifications, including all required features, tolerances, and surface finishes. This turnkey approach eliminates your machining coordination and ensures components arrive ready for assembly.

Ideal for: Clients who want complete manufacturing coordination and guaranteed dimensional accuracy

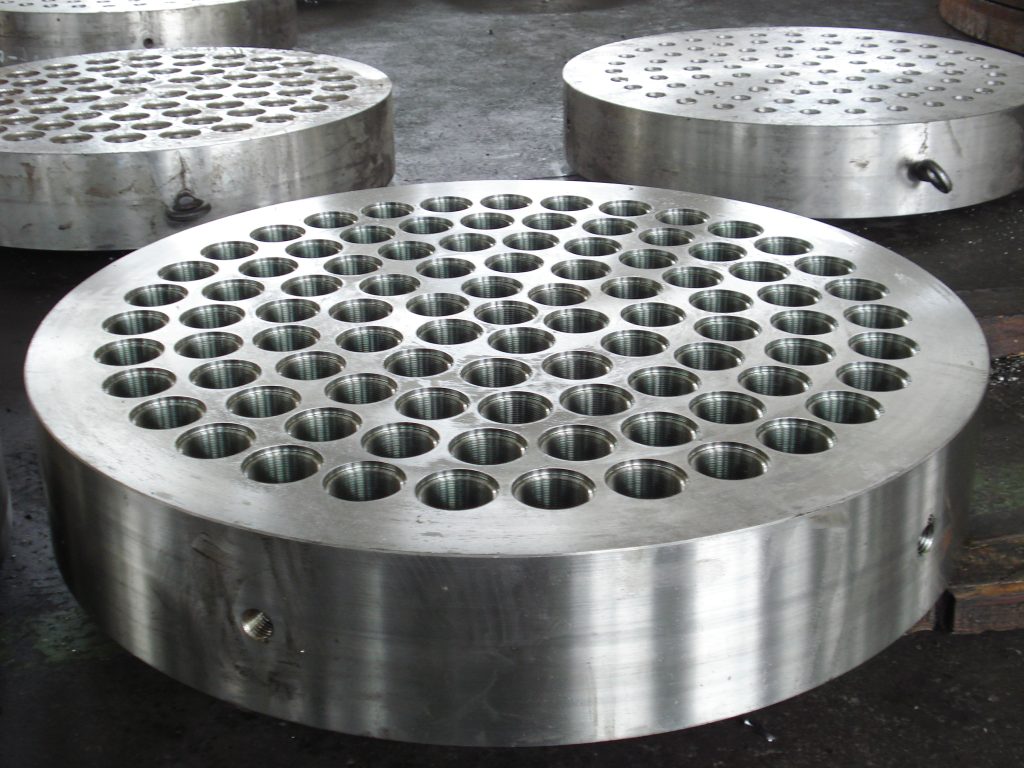

Our network includes facilities capable of precision machining for components up to 8.5+ meters in diameter. These specialized facilities have the equipment and expertise to maintain tight tolerances even on massive components.

From intricate profiles to specialized drilling patterns, we coordinate machining operations for components with complex geometries that require multi-axis machining capabilities and specialized tooling.

We coordinate machining operations with heat treatment processes to ensure optimal material properties while maintaining dimensional stability. This integrated approach prevents costly rework and ensures consistent quality.

Our network includes facilities capable of achieving tolerances to tenths of millimeters on critical dimensions, with the quality systems necessary to verify and document these measurements.

We implement inspection procedures at critical stages of the machining process, identifying potential issues before they impact final dimensions. Our proactive approach prevents costly rework and delays.

We provide complete documentation of machining operations, including dimensional reports, material certifications, and any specialized testing required by your specifications.

Throughout the machining process, we maintain regular communication with both our clients and machining facilities, providing updates on progress and immediate notification of any issues that arise.

For a critical crane component weighing nearly 10 tons, we coordinated precision machining of threaded features that required exact tolerances for proper assembly. The project included creating test components from plastic to verify fit before final machining.

We've delivered compact flanges requiring extreme dimensional accuracy for metal-to-metal sealing applications. These components require precision machining that many facilities cannot achieve, particularly when combined with specialized material requirements.

For metal bending equipment, we've coordinated production of precision wheels requiring exact dimensional control through forging, heat treatment, and final machining. These components must maintain precise tolerances while achieving the surface hardness needed for extended service life.

When clients face urgent needs for machined components, our network allows us to identify available capacity and expedite production. While premium pricing applies for rush orders, we can significantly compress standard machining timelines when your operation requires it.

Contact us for a no-obligation consultation. We’ll analyze your machining needs and provide realistic options that match your timeline and specifications.

Download our whitepaper and gain practical insights into materials, quality, and supply reliability.