Welding and cladding for forged components: When to combine processes

Forging vs casting vs fabrication: Which delivers the best performance by By Pro Steel Supply December 24, 2024 Forged components are designed to endure extreme pressure, heat and corrosion. Yet in many industries, the base material alone is not enough. To meet demanding service conditions, engineers often rely on welding and metal cladding to enhance […]

Designing for forging: How engineers can save weeks in production

Forging vs casting vs fabrication: Which delivers the best performance by By Pro Steel Supply December 24, 2024 Every project begins with a drawing, but the way that drawing is created determines how fast it becomes a finished part. In the world of forging, a well-designed component can move through production smoothly and predictably, while […]

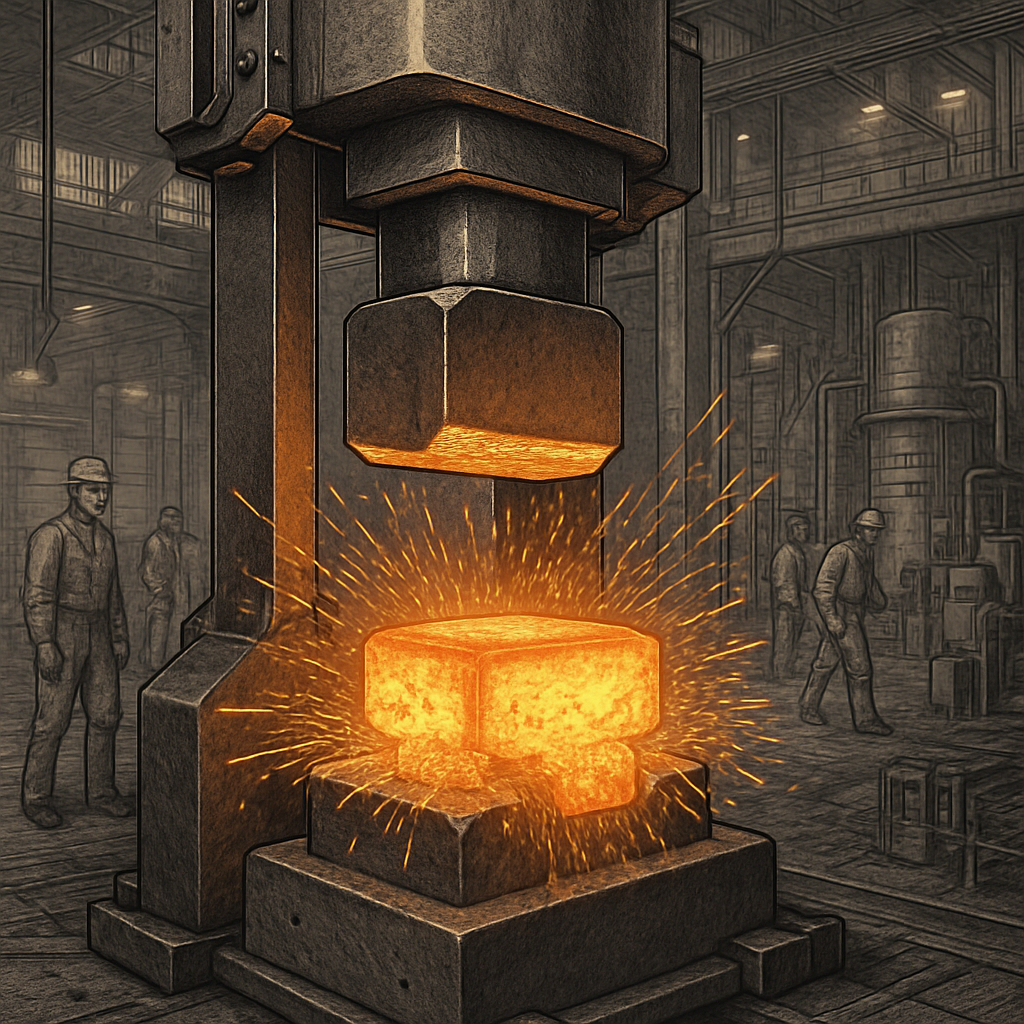

Forging vs casting vs fabrication: Which delivers the best performance

Heat treatment timing: Why sequence matters in forged components by By Pro Steel Supply December 24, 2024 Every component in heavy industry begins as a simple idea on paper and ends as metal under pressure, heat or weld. Between that beginning and the final product lies a decision that defines how long the part will […]

European vs Chinese forging: Quality, cost, and supply chain considerations

European vs Chinese forging: Quality, cost, and supply chain considerations by By Pro Steel Supply December 24, 2024 When procurement teams evaluate forging suppliers, the choice between European and Chinese manufacturers often comes down to a simple assumption: European equals premium quality at premium prices, Chinese equals acceptable quality at budget prices. This oversimplification can […]

Heat treatment timing: Why sequence matters in forged components

Heat treatment timing: Why sequence matters in forged components by By Pro Steel Supply December 24, 2024 A perfectly forged component can become expensive scrap in minutes if heat treatment occurs at the wrong time in the manufacturing sequence. Yet many purchasers—and even some manufacturers—don’t fully understand the critical relationship between forging, machining, and heat […]

From 3 to 8.5 meters: How offshore wind changed forging requirements

From 3 to 8.5 meters: How offshore wind changed forging requirements by By Pro Steel Supply December 24, 2024 Twenty years ago, offshore wind turbines stood on monopiles barely 3 meters in diameter. Today, the latest installations require foundation structures exceeding 8.5 meters across. This dramatic evolution hasn’t just changed the landscape of renewable energy—it’s […]

Decoding material certificates: 3.1 vs 3.2 and why it matters

Decoding material certificates: 3.1 vs 3.2 and why it matters by By Pro Steel Supply December 24, 2024 When your project depends on material performance, the certificate that accompanies your forged components isn’t just paperwork—it’s your assurance that the material will perform as specified. Yet many purchasers don’t fully understand the crucial differences between material […]