A perfectly forged component can become expensive scrap in minutes if heat treatment occurs at the wrong time in the manufacturing sequence. Yet many purchasers—and even some manufacturers—don’t fully understand the critical relationship between forging, machining, and heat treatment timing.

Getting the sequence wrong doesn’t just affect material properties—it can make your components impossible to machine to final specifications.

Heat treatment isn’t just about achieving target hardness or strength values. It’s about optimizing material properties while maintaining dimensional stability throughout the manufacturing process. The timing of heat treatment relative to other manufacturing steps can determine whether your components meet specifications or become costly rejects.

Most people understand that heat treatment changes material properties. What’s less understood is how it affects machining operations, dimensional stability, and the interaction between different manufacturing processes.

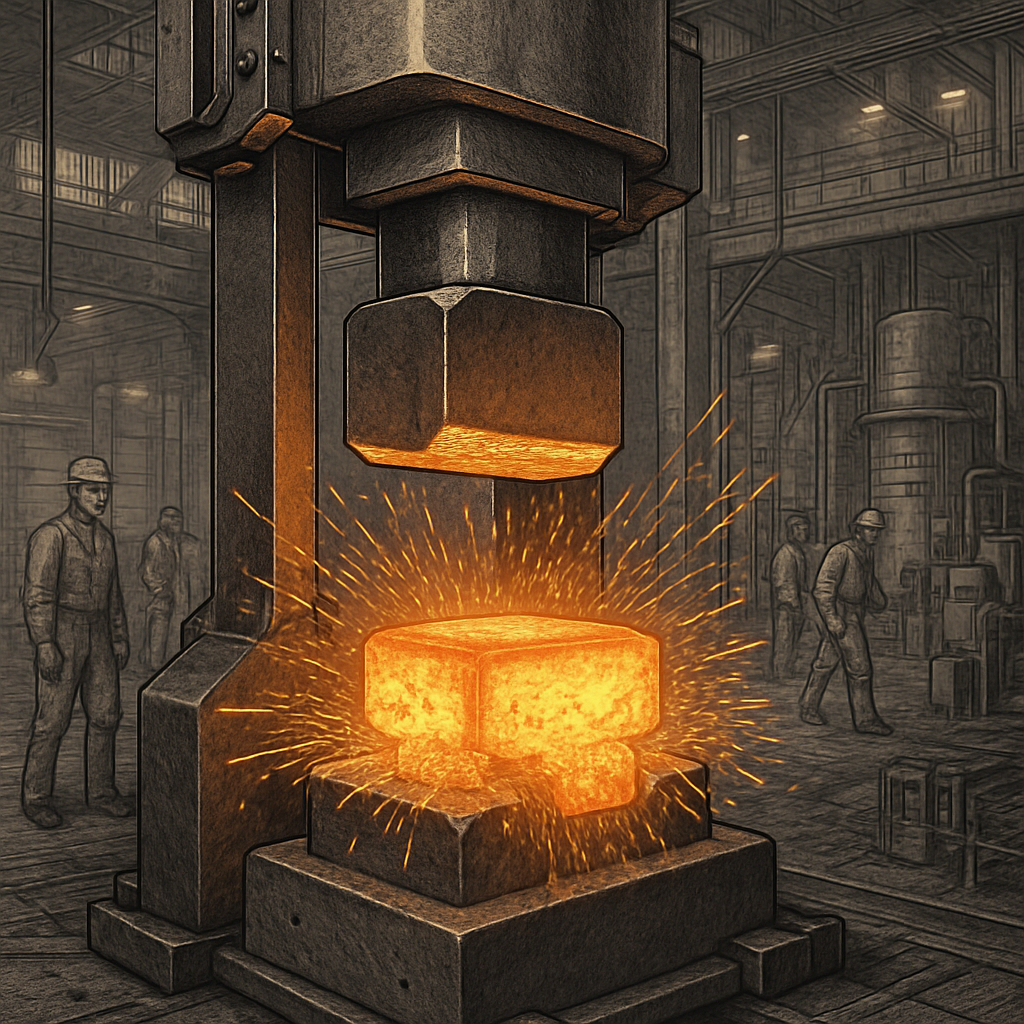

When steel is heated and cooled during heat treatment, several things happen simultaneously that affect subsequent manufacturing operations.

Forging introduces internal stresses into the material structure. These stresses can cause components to warp or change dimensions during machining operations. Heat treatment can relieve these stresses—but only if performed at the right time in the sequence.

The forging process creates a grain structure that affects material properties and machinability. Heat treatment can optimize this grain structure, but the timing determines whether the benefits are preserved through subsequent operations.

Heat treatment affects surface condition, which impacts both machining operations and final component performance. Performing heat treatment at the wrong time can create surface conditions that are difficult or impossible to machine properly.

This sequence optimizes material properties early but creates machining challenges.

Advantages:

Disadvantages:

This sequence balances material optimization with machining practicality.

Advantages:

Disadvantages:

This sequence prioritizes machining convenience but may compromise performance.

Advantages:

Disadvantages:

Different industries have developed preferred sequences based on their specific performance requirements and risk tolerance.

These applications typically use sequence 2 (forge → rough machine → heat treat → finish machine) because:

Many industrial applications use sequence 1 (forge → heat treat → machine) because:

These applications often require sequence 2 with additional verification steps:

Successful heat treatment timing requires careful coordination between multiple suppliers and processes, each with their own scheduling and capability constraints.

Heat treatment facilities often operate around the clock, but machining operations may have more limited schedules. Coordinating these different operating patterns while maintaining optimal timing requires careful planning.

Components may need to move between different facilities for forging, heat treatment, and machining. Transportation time and logistics become part of the timing equation.

Inspection and testing must occur at appropriate points in the sequence. Testing too early may not reflect final component properties, while testing too late may discover problems that are expensive to correct.

A manufacturer of industrial wheels decided to heat treat components after final machining to save costs. The heat treatment caused dimensional changes that put the wheels outside specification tolerances. The entire batch—worth over $50,000—had to be scrapped because post-heat-treatment machining wasn’t possible due to surface hardness.

A pressure vessel manufacturer used the forge → rough machine → heat treat → finish machine sequence for critical components. When heat treatment caused slight warping, the finish machining operation corrected the dimensions while maintaining optimal material properties. The components have now operated successfully for over 15 years in a demanding chemical processing environment.

The optimal heat treatment timing depends on several factors specific to your application and requirements.

What’s your risk tolerance for scrap or rework? More complex sequences have more potential failure points but also more correction opportunities.

The best forging suppliers understand these timing considerations and can guide you toward the optimal sequence for your specific requirements.

Suppliers who coordinate the entire manufacturing sequence—forging, heat treatment, and machining—can optimize timing for your specific requirements rather than optimizing individual processes in isolation.

This integration allows for:

Successful heat treatment timing starts with clear specification of final requirements and honest discussion of trade-offs with your manufacturing partner.

The goal isn’t to choose the cheapest sequence, but to select the approach that delivers the performance you need while managing risks appropriately for your application.

Ready to optimize your heat treatment timing strategy? Contact us for a consultation on the optimal manufacturing sequence for your specific components.