Every component in heavy industry begins as a simple idea on paper and ends as metal under pressure, heat or weld. Between that beginning and the final product lies a decision that defines how long the part will last. Should it be forged, cast or fabricated

Each process has its advantages, but when performance matters, understanding how they differ is essential. The way metal is formed determines everything from structural strength to corrosion resistance, and ultimately, reliability in the field.

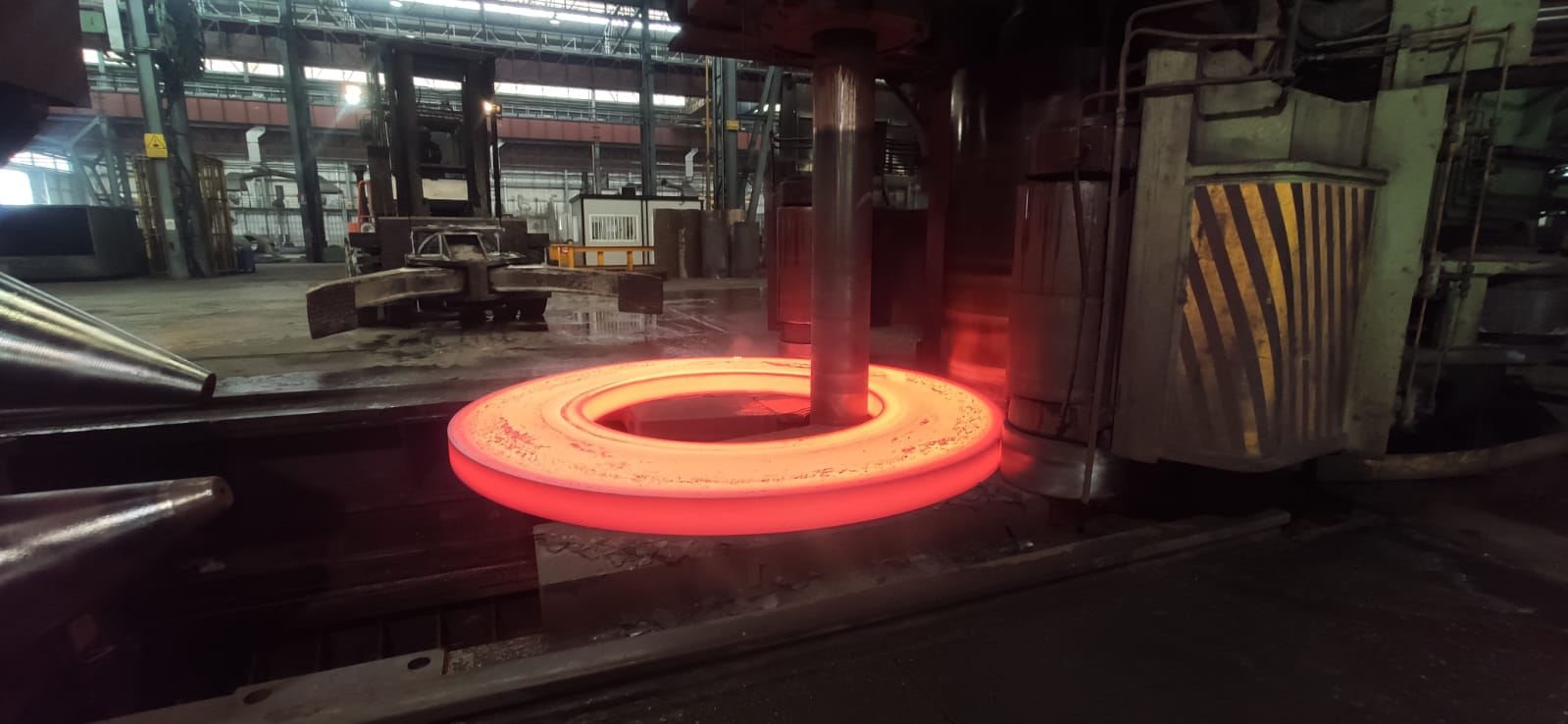

Forging shapes solid metal through immense compressive force. Instead of melting, the steel is pressed and deformed until it takes on the desired geometry. This process refines the internal grain structure, aligning it with the shape of the part. The result is exceptional strength, toughness and fatigue resistance.

Forged components are often used where failure is unacceptable. Offshore connectors, pressure vessel flanges, turbine shafts and defense components rely on the consistent grain flow that only forging can achieve. Each impact during the forging process improves density and eliminates internal voids that could cause cracking later in service.

The precision of modern forging also allows near net shapes, reducing waste and machining time. For large rings or complex geometries, ring rolling and open die forging can deliver parts weighing from a few kilos to several tons, ready for finishing. The trade off is higher production cost and longer lead time, but the return is unmatched reliability.

Casting begins where forging stops. Instead of pressure, it uses heat. The metal is melted and poured into a mold where it cools and solidifies. This allows engineers to produce complex geometries that would be impossible to forge in one piece.

There are many casting methods, but two dominate in industrial production: die casting and sand casting.

Die casting uses high pressure to inject molten metal into a reusable steel mold. It delivers excellent dimensional accuracy and smooth surfaces, making it ideal for smaller components in automotive or machinery applications.

Sand casting, on the other hand, uses disposable sand molds that can hold very large parts. It is flexible and cost effective for low volume production, though surface finish and internal consistency depend heavily on process control.

The challenge with casting lies beneath the surface. Porosity, inclusions and inconsistent cooling can weaken the final product. For low stress parts, this may not matter, but in critical environments, even a small defect can lead to failure. That is why cast components often require extensive testing before approval.

Metal fabrication and steel fabrication take a different route. Instead of shaping molten or solid metal, fabrication assembles multiple pieces into one structure. It involves cutting, bending, drilling and welding pre-rolled plates or bars.

Fabrication is the backbone of large industrial and construction projects. When a single forged or cast piece would be too large or uneconomical, fabrication steps in. It allows fast customization, easy repairs and scalable production of frames, tanks or pressure vessels.

However, every weld becomes a potential weak point. Welded joints can introduce residual stresses or misalignment if not properly controlled. For low pressure or structural applications, this is acceptable. For components exposed to fatigue, vibration or corrosion, it can be a serious limitation.

When comparing these three processes, several key factors define performance: strength, reliability, cost and flexibility.

Forging produces the strongest parts. The dense, aligned grain structure resists fatigue and impact far better than cast or fabricated metal. Castings are more brittle, while fabricated parts depend heavily on weld quality.

Casting and fabrication win here. Die casting produces precise shapes without machining. Sand casting allows huge dimensions with flexible mold design. Fabrication can build almost any geometry by welding plates together.

Casting is the most cost effective for high volume production. Fabrication offers moderate cost and quick turnaround for custom projects. Forging demands higher investment but pays off in longevity and reliability over time.

Selecting the right process is not just about price or appearance. It is about matching the method to the operating conditions. A forged ring on an offshore platform faces constant stress and corrosion; it must perform for decades. A cast pump housing in a factory can be replaced more easily and cheaply. A fabricated tank may only need moderate pressure resistance but high volume capacity.

Engineers often use a combination of all three. A large assembly may include forged flanges for high pressure connections, cast housings for complex shapes and fabricated frames for support. Understanding where each process excels allows better design decisions and cost control.

Every production method involves tradeoffs. Forging takes longer and costs more, but it virtually eliminates the risk of internal defects. Casting is fast and efficient but can hide imperfections. Fabrication is versatile but depends on inspection and welding precision.

In industries like oil and gas, marine and defense, risk tolerance is low. A failed forged component can stop a project, but a casting flaw or weld crack can do the same, only faster. That is why project managers often prioritize proven forging suppliers for safety critical components, even when budgets are tight.

Technology continues to narrow the gap between these processes. Modern forges use computer controlled presses and simulation software to optimize metal flow. Foundries now employ vacuum casting and real time x-ray inspection to improve quality. Fabrication shops use robotic welding and automated cutting to increase precision.

Still, the core truth remains. When the goal is ultimate mechanical performance and reliability under stress, forging stands above the rest. Casting and fabrication will always have their place, but forging delivers the confidence that every grain of metal is working in your favor.

Successful supplier relationships require appropriate quality assurance approaches that match the supplier’s capabilities and your requirements.

European suppliers often have established quality systems that require less active oversight:

Chinese suppliers may require more active quality management:

The optimal supplier choice depends heavily on your specific application requirements and risk tolerance.

For applications where component failure has catastrophic consequences:

For applications with high volume requirements and cost sensitivity:

For applications requiring specialized expertise or unique capabilities:

Geographic supplier selection creates different supply chain risks that must be managed appropriately.

Successful supplier selection requires moving beyond geographic generalizations to evaluate specific capabilities, quality systems, and cost structures.

Many successful companies use a combination of European and Chinese suppliers, matching supplier capabilities to specific application requirements.

Companies that successfully navigate the European vs Chinese supplier decision often work with supply chain specialists who understand both manufacturing landscapes and can provide guidance on supplier selection, quality management, and risk mitigation.

These specialists can:

The choice between European and Chinese forging suppliers shouldn’t be based on geographic stereotypes but on careful evaluation of specific supplier capabilities, quality systems, and total cost of ownership for your particular requirements.

The best suppliers—regardless of location—combine technical capability, quality systems, and cost competitiveness to deliver value for their customers. The worst suppliers—also regardless of location—compete primarily on price while compromising quality and reliability.

Success requires understanding these nuances and making supplier decisions based on facts rather than assumptions.

Ready to evaluate your forging supplier options? Contact us for guidance on selecting suppliers that match your specific requirements and risk tolerance.