Forged components are designed to endure extreme pressure, heat and corrosion. Yet in many industries, the base material alone is not enough. To meet demanding service conditions, engineers often rely on welding and metal cladding to enhance the surface properties of forged steel.

Knowing when to combine these processes is essential for creating components that last. The right combination of forging and surface treatment can extend service life, reduce maintenance and save significant cost over time.

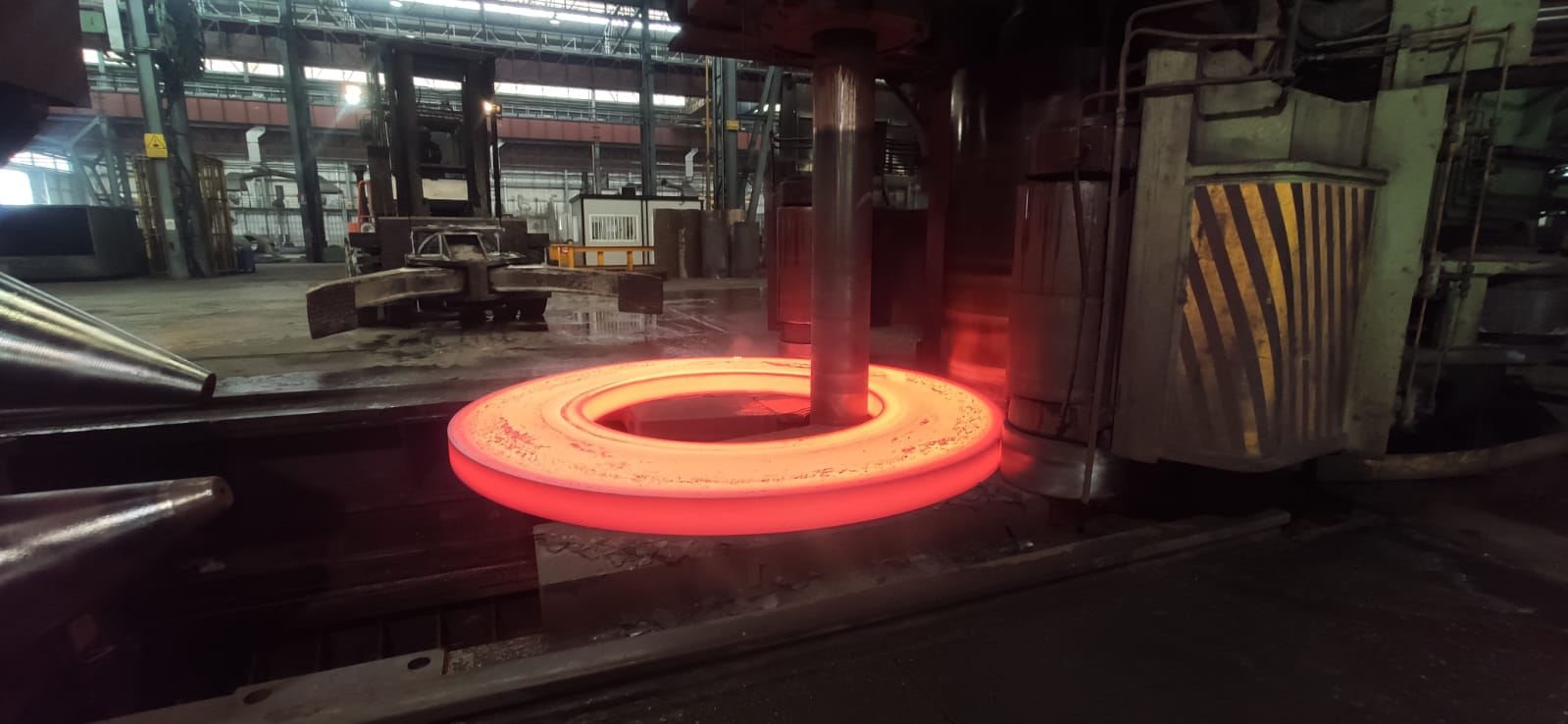

Forging produces dense, high-strength metal with excellent fatigue resistance. However, when these parts operate in aggressive environments such as chemical plants, refineries or offshore platforms, corrosion and wear become critical challenges.

A forged flange or valve body may have the ideal mechanical properties, but without additional protection, its surface can deteriorate quickly. This is where metal cladding and overlay welding come in. These processes allow engineers to create a corrosion-resistant surface while maintaining the strength of the forged base material underneath.

Metal cladding is the process of bonding a layer of corrosion-resistant alloy onto a base metal. The purpose is to protect the component from wear, temperature and chemical attack while keeping costs lower than using a solid exotic alloy.

For example, instead of manufacturing an entire flange from Inconel or stainless steel, a carbon steel forging can be clad with a thin layer of that material on the exposed surfaces. The result combines the strength and affordability of forged steel with the corrosion resistance of premium alloys.

Common cladding methods include overlay welding, explosion bonding and roll bonding, each offering different levels of metallurgical bonding and surface quality.

Overlay welding is one of the most common techniques used for applying protective layers to forged components. It involves depositing molten filler metal onto the surface of a part using controlled welding techniques such as gas tungsten arc welding (GTAW), submerged arc welding (SAW) or plasma transferred arc welding (PTA).

The process builds up a layer of alloy with full metallurgical fusion to the substrate, ensuring durability under pressure and high temperature. Overlay welding allows precise control of the cladding thickness and composition, making it ideal for pressure vessels, heat exchangers and pipeline flanges.

By adjusting parameters such as current, travel speed and filler material, engineers can achieve consistent bonding with minimal dilution between the cladding and the base metal.

Inconel cladding is widely used where high temperature and corrosion resistance are critical, such as in offshore or chemical applications. Inconel alloys maintain strength even under extreme heat and resist oxidation, making them perfect for surfaces exposed to aggressive chemicals or seawater.

Other popular alloys for cladding include stainless steel, Monel and duplex materials. The selection depends on the environment, temperature range and chemical exposure. Choosing the right alloy requires balancing mechanical performance, weldability and cost.

Integrating welding and cladding with forging allows manufacturers to optimize performance while minimizing material costs. A forged body provides the strength and shape accuracy, while cladding or overlay adds the protective barrier exactly where it is needed.

This approach also simplifies repair and refurbishment. Damaged or worn surfaces on forged parts can often be rebuilt using overlay welding rather than replacing the entire component. In industries where downtime is expensive, this flexibility makes a significant difference.

Combining forging, welding and cladding requires strict process control. Each stage must maintain the integrity of the previous one. Preheat and post-weld heat treatment are essential to avoid cracking or distortion.

Inspection techniques such as ultrasonic testing, dye penetrant inspection and hardness measurement verify the quality of both the weld and the clad layer. Maintaining consistent parameters during welding techniques ensures uniform bonding and prevents defects that could lead to premature failure.

Using metal cladding and overlay welding on forged components offers the best of both worlds. Engineers get the mechanical strength of forging and the corrosion resistance of advanced alloys like Inconel.

This hybrid approach reduces total lifecycle costs, improves performance and ensures that critical equipment continues to operate safely under extreme conditions. When applied correctly, these processes do not just protect steel; they preserve productivity.

Selecting the right process is not just about price or appearance. It is about matching the method to the operating conditions. A forged ring on an offshore platform faces constant stress and corrosion; it must perform for decades. A cast pump housing in a factory can be replaced more easily and cheaply. A fabricated tank may only need moderate pressure resistance but high volume capacity.

Engineers often use a combination of all three. A large assembly may include forged flanges for high pressure connections, cast housings for complex shapes and fabricated frames for support. Understanding where each process excels allows better design decisions and cost control.

Every production method involves tradeoffs. Forging takes longer and costs more, but it virtually eliminates the risk of internal defects. Casting is fast and efficient but can hide imperfections. Fabrication is versatile but depends on inspection and welding precision.

In industries like oil and gas, marine and defense, risk tolerance is low. A failed forged component can stop a project, but a casting flaw or weld crack can do the same, only faster. That is why project managers often prioritize proven forging suppliers for safety critical components, even when budgets are tight.

Technology continues to narrow the gap between these processes. Modern forges use computer controlled presses and simulation software to optimize metal flow. Foundries now employ vacuum casting and real time x-ray inspection to improve quality. Fabrication shops use robotic welding and automated cutting to increase precision.

Still, the core truth remains. When the goal is ultimate mechanical performance and reliability under stress, forging stands above the rest. Casting and fabrication will always have their place, but forging delivers the confidence that every grain of metal is working in your favor.

Successful supplier relationships require appropriate quality assurance approaches that match the supplier’s capabilities and your requirements.

European suppliers often have established quality systems that require less active oversight:

Chinese suppliers may require more active quality management:

The optimal supplier choice depends heavily on your specific application requirements and risk tolerance.

For applications where component failure has catastrophic consequences:

For applications with high volume requirements and cost sensitivity:

For applications requiring specialized expertise or unique capabilities:

Geographic supplier selection creates different supply chain risks that must be managed appropriately.

Successful supplier selection requires moving beyond geographic generalizations to evaluate specific capabilities, quality systems, and cost structures.

Many successful companies use a combination of European and Chinese suppliers, matching supplier capabilities to specific application requirements.

Companies that successfully navigate the European vs Chinese supplier decision often work with supply chain specialists who understand both manufacturing landscapes and can provide guidance on supplier selection, quality management, and risk mitigation.

These specialists can:

The choice between European and Chinese forging suppliers shouldn’t be based on geographic stereotypes but on careful evaluation of specific supplier capabilities, quality systems, and total cost of ownership for your particular requirements.

The best suppliers—regardless of location—combine technical capability, quality systems, and cost competitiveness to deliver value for their customers. The worst suppliers—also regardless of location—compete primarily on price while compromising quality and reliability.

Success requires understanding these nuances and making supplier decisions based on facts rather than assumptions.

Ready to evaluate your forging supplier options? Contact us for guidance on selecting suppliers that match your specific requirements and risk tolerance.