“Show me the heat number.”

The inspector’s voice was calm but firm. He held up the flange. 3 meters diameter. Duplex stainless. Ready for installation on a North Sea platform.

“It’s on the paperwork,” the project manager replied.

“I need to see it stamped on the component. And I need the mill certificate showing that exact heat number. And the forge certificate. And the heat treatment chart. All matching.”

The project manager’s face went pale. The paperwork was in order. But could he trace this specific forging back to the steel mill? Back to the exact batch of raw material?

He couldn’t. The installation stopped. The component was rejected. Eight weeks of delay while a replacement with proper traceability was sourced.

Welcome to high-stakes forging projects. Where certificate management isn’t paperwork bureaucracy. Where heat tracing isn’t optional documentation. Where material control determines whether your €100,000 component gets installed or rejected.

After 30 years coordinating forging supply chains, we’ve learned one truth: traceability protects projects. Lack of traceability destroys them.

This article explains what traceability means, why it matters, and how proper material control prevents expensive project failures.

Traceability is the ability to track a component back through its entire manufacturing history to the source material.

For a forged component, complete traceability means you can identify:

This isn’t abstract information. It’s documented, verified, and physically marked on the component.

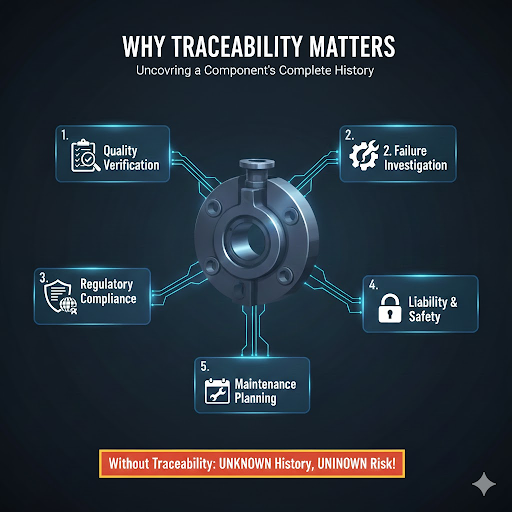

Traceability serves multiple critical purposes:

Quality verification: Proves the component meets specifications and was produced correctly.

Failure investigation: If problems occur, traceability identifies affected components and root causes.

Regulatory compliance: Offshore, nuclear, and aerospace applications legally require full traceability.

Warranty and liability: Defines responsibility if defects are discovered years after installation.

Maintenance planning: Informs inspection intervals and replacement decisions over component lifetime.

Without traceability, you have a metal component with unknown history. You’re hoping it meets specifications. You’re assuming it was made correctly. You’re guessing about its properties.

That’s acceptable for low-stakes applications. It’s unacceptable for offshore platforms, pressure vessels, or safety-critical equipment.

Complete traceability requires documentation at every production stage. Break the chain anywhere and traceability is lost.

Traceability starts at the steel mill. Steel is produced in batches called “heats.” Each heat is assigned a unique heat number.

What the steel mill documents:

This information is recorded on a mill certificate. For offshore and critical applications, this is typically an EN 10204 3.1 certificate.

The heat number is physically stamped or marked on the steel product.

When the forge receives steel, they verify heat number markings match mill certificate, material grade is correct, and certificates are complete.

During forging, the forge must maintain heat tracing:

The forge issues a forge certificate showing original mill heat number, chemical composition, mechanical properties, heat treatment details, and inspection results.

If the forging is machined after leaving the forge, the machine shop must:

Heat tracing cannot be lost during machining. If heat stamps are machined away, new markings must be applied and documented.

At the fabrication yard or installation site:

This final step closes the traceability loop. Years later, if inspection or maintenance is needed, you know exactly which component is installed and its complete history.

Maintaining traceability requires managing extensive documentation. For a large offshore project with hundreds of forgings, this can mean thousands of certificates.

Typical certificate package for a critical forging includes:

For a single component, this can be 10-20 pages of documentation.

Certificate management failures cause project delays:

These problems are common. They’re also preventable through proper certificate management systems.

Successful projects implement systematic certificate management:

Digital systems: Scan all certificates on receipt. Store in searchable database. Link to component identification.

Verification on receipt: Check certificates against physical markings immediately. Resolve discrepancies before components enter storage.

Organized filing: Maintain both digital and physical certificate files. Organize by component ID, heat number, and installation location.

Backup copies: Multiple copies stored in different locations. Critical projects maintain off-site backup.

Access control: Define who can access, modify, and approve certificate documentation. Maintain change logs.

Audit trail: Document when certificates were received, verified, and filed.

These systems prevent the “we can’t find the certificate” crisis during installation or years later during maintenance.

Heat tracing is the physical link between documentation and components. Without proper marking, certificates are meaningless.

Physical marking methods:

For critical components, permanent markings (stamping or engraving) are required. Tags or paint are supplementary only.

Minimum marking typically includes:

At each handoff point, markings are verified:

This catches errors before they reach the field where correction is expensive.

Heat tracing prevents mix-ups. Material control is the system that makes heat tracing reliable.

Forges and fabrication yards handle multiple orders simultaneously. Different materials. Different specifications. Similar appearances.

Mix-ups occur when:

A mix-up can mean installing the wrong material grade in a critical application. Carbon steel where stainless was specified. Standard duplex where superduplex was required.

The consequences are severe. Component failure. Safety incidents. Liability. Project delays.

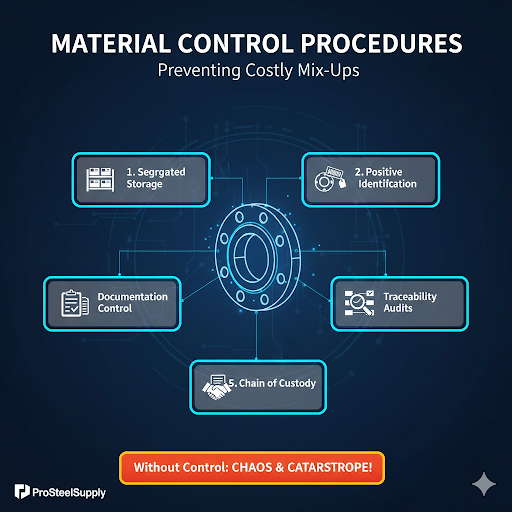

Preventing mix-ups requires systematic material control:

Segregated storage: Different materials stored in separate locations. Clear labeling of storage areas.

Positive identification: Every component clearly marked and tagged. Verification before any operation.

Documentation control: Certificates attached to correct components. Verification at every handoff.

Traceability audits: Periodic checks that physical components match documentation.

Chain of custody: Documented handoffs between organizations. Sign-off that identity was verified.

These procedures are standard in nuclear, aerospace, and offshore industries. They should be standard wherever material mix-up would be catastrophic.

Proper traceability has saved projects from expensive failures.

A steel mill discovered that one production heat had elevated sulfur content. Out of specification but only by a small margin. The heat had been shipped to multiple forges over three months.

With proper heat tracing:

Total affected: 47 forgings across 12 projects. All identified within days. Some accepted after engineering review. Some replaced. No failures occurred.

Without heat tracing: Those 47 forgings would be in unknown locations. Waiting for failures to reveal themselves.

An offshore platform experienced a flange failure after 3 years service. Failure analysis showed improper heat treatment.

With proper traceability:

Without traceability: Only the failed component would be known. The other at-risk components would remain in service, waiting to fail.

During pre-installation verification, an inspector noticed the heat number stamped on a component didn’t match the heat number on the certificate.

Investigation revealed:

Without verification: Wrong certificate would have been filed. Future traceability would be broken.

After 30 years coordinating forging supply chains, we’ve built systems that ensure traceability.

Our Certificate Management System:

We maintain digital certificate database for every component we supply. All mill certificates, forge certificates, test reports, inspection records. Linked to heat numbers and customer references. Searchable and backed up continuously.

When you need documentation years after delivery, we have it.

Our Heat Tracing Verification:

We verify heat tracing at multiple points. When steel arrives at forge. When forgings are produced. When components ship. When components arrive at customer.

This catches errors before they reach the field.

Our Material Control Procedures:

We work only with forges that have robust material control. Segregated storage by material grade and heat. Positive identification at every operation. Regular traceability audits. Documented chain of custody.

These procedures prevent mix-ups that create liability and safety risks.

Our Traceability Support:

We help customers implement traceability systems. Define what traceability is required. Structure documentation packages appropriately. Train receiving inspection personnel. Provide as-built documentation. Support investigations if problems occur years later.

Traceability protects high-stakes projects. It proves components meet specifications. It enables root cause analysis if failures occur. It satisfies regulatory requirements. It defines liability and responsibility.

Yes, proper traceability costs more. Certificate management systems. Heat tracing verification. Material control procedures. All add expense.

But compare these costs to project risks. Installing unknown material in a subsea pressure vessel. Unable to identify affected components when defects are discovered. Regulatory rejection due to incomplete documentation.

The projects that succeed implement traceability from the start. Clear requirements. Qualified suppliers with proper systems. Verification at every handoff. Documentation maintained for decades.

Need forgings with complete traceability? ProSteel Supply coordinates traceability from steel mill to installation. We verify heat numbers. We manage certificates. We implement material control that prevents mix-ups.

Contact us for traceability guidance. Because in high-stakes projects, knowing what you installed matters as much as what you installed.

Download our whitepaper and gain practical insights into materials, quality, and supply reliability.