“Can you source this in Europe? We need NORSOK certification.”

“Yes. Lead time is 22 weeks and the price is €85,000.”

“What if we’re flexible on origin?”

“Then we have options. Let me show you what’s possible.”

This conversation happens weekly. Clients assume European sourcing means European manufacturing. It doesn’t.

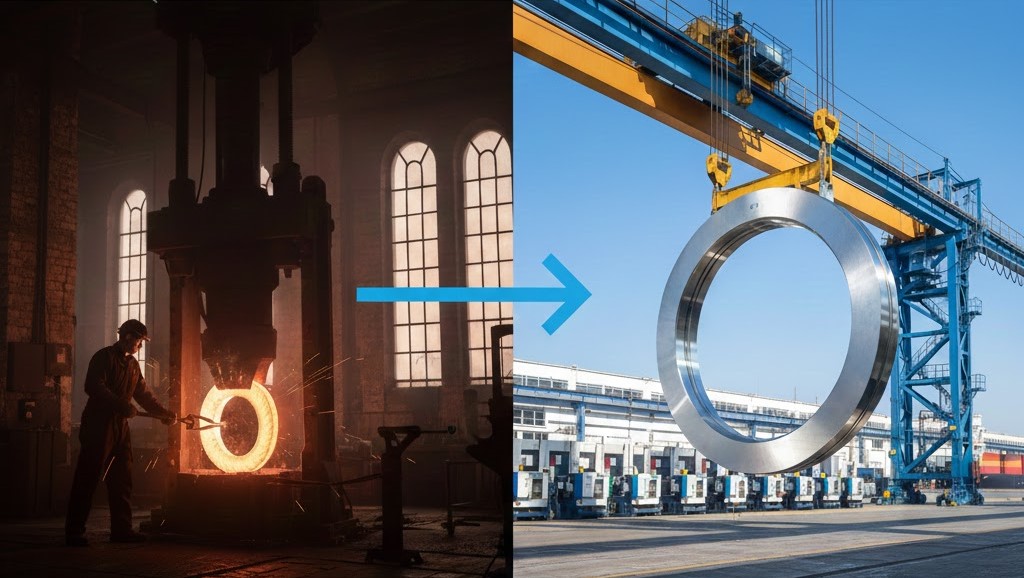

After 30 years building a forge network across continents, we learned one truth: the best sourcing solution combines European quality standards with global manufacturing capacity.

This article explains how international sourcing delivers better outcomes than regional limitations.

European forges built their reputation over centuries. German precision. Italian craftsmanship. Scandinavian innovation.

That reputation is earned.

European forges pioneered ring rolling technology. They developed duplex and superduplex metallurgy. They hold NORSOK M-650 qualifications. They maintain relationships with Lloyd’s, DNV, and Bureau Veritas inspectors.

When offshore operators specify “European origin,” they’re specifying proven capability and established quality systems.

But European capacity has limits.

Europe has approximately 40 forges capable of producing offshore-grade components.

Only 12 can produce rings above 4 meters diameter.

Only 8 hold current NORSOK M-650 qualifications for superduplex.

Only 5 have heat treatment capacity for large nickel alloy forgings.

When oil prices rise and offshore activity increases, these forges book solid for 12+ months. Your project waits or pays premium expediting fees.

Geography creates bottlenecks.

European labor costs, energy costs, and regulatory compliance costs are high. A duplex ring forging in Germany costs 30 to 40% more than the same forging in South Korea or China.

For some applications, that premium buys necessary certification and proven performance. For others, it’s paying extra for capability you don’t need.

Smart international sourcing distinguishes between the two.

Twenty years ago, Asian forges meant compromised quality. Not anymore.

South Korean, Chinese, and Japanese forges invested billions in modern equipment, quality systems, and technical expertise. They hired European metallurgists. They obtained ISO certifications. They qualified for class society approvals.

Today, Asian forges produce forgings that meet the same technical standards as European manufacturers. Often at significantly lower cost.

Modern equipment: Asian forges installed the same Waldrich, Lasco, and SMS ring rolling equipment as European competitors.

Quality systems: ISO 9001, API Q1, and pressure equipment directive certifications became standard.

Technical expertise: Metallurgists trained in European and American universities brought knowledge back home.

Class society presence: DNV, Lloyd’s, and ABS established Asian offices and inspector networks.

The capability gap closed.

Large diameter rings: Chinese forges have the world’s largest ring rolling capacity. Rings up to 12 meters diameter.

Volume production: Asian forges handle series production more efficiently than European job shops.

Cost: Significantly lower manufacturing costs on equivalent quality.

Lead time: When European forges are booked solid, Asian capacity often has availability.

NORSOK qualification: Most NORSOK M-650 qualified forges remain European.

Complex specifications: European forges handle one-off custom requirements more flexibly.

Subsea certification depth: Decades of offshore North Sea experience.

Close coordination: Time zones and proximity matter for complex technical discussions.

The smart approach uses both.

Not every forging needs European manufacturing. Not every forging should use Asian manufacturing. The key is matching capability to requirement.

NORSOK certification required

Complex subsea specifications

Small custom orders

Close technical coordination needed

Client specification mandates European origin

We source from Germany, Italy, Spain, Czech Republic, and Poland for these applications.

Large diameter rings (8+ meters)

Volume production runs

Cost sensitivity with standard specifications

European forge capacity constraints

Standard ASTM or EN specifications

We source from South Korea, China, and Japan for these applications.

Many projects use both. European forges for critical certified components. Asian forges for standard support components.

Example: Subsea manifold project. Main pressure housing from NORSOK-qualified German forge. Support rings and mounting flanges from Korean forge at 40% lower cost.

Total project cost optimized. Critical specifications met. Delivery on schedule.

That’s smart international sourcing.

Managing a global forge network requires different processes than managing local suppliers.

For every forge in our network, we:

Visit facilities personally. Inspect equipment, review quality systems, meet technical staff.

Review certifications. ISO certificates, class society approvals, customer references.

Run trial orders. Small production runs to validate capability before committing large projects.

Track performance. On-time delivery, quality issues, responsiveness, communication.

This takes years to build and constant effort to maintain.

Adding a new forge to our network follows strict steps:

Initial assessment: Review certifications, equipment capability, customer base.

Site visit: Physical inspection of facilities, equipment, and quality systems.

Trial production: Small order to validate quality, communication, and delivery.

Performance monitoring: Track multiple orders before full qualification.

Timeline: 12 to 18 months from initial contact to full qualification.

We don’t add forges casually. Our network represents decades of relationship building.

International sourcing means international logistics. A 5-meter diameter duplex ring weighs 8 tons. It doesn’t fit in a standard container.

From Asia to Europe, logistics adds:

Time: 6 to 8 weeks for sea freight

Cost: €3,000 to 8,000 depending on size and weight

Complexity: Customs clearance, import documentation, delivery coordination

Freight forwarding relationships: Partnerships with specialized heavy equipment forwarders.

Custom crating specifications: Working with forges to ensure proper packaging for international transport.

Documentation management: Handling customs paperwork, certificates of origin, import licenses.

Delivery tracking: Real-time visibility into shipment location and status.

This infrastructure took years to build. It’s invisible to clients until something goes wrong.

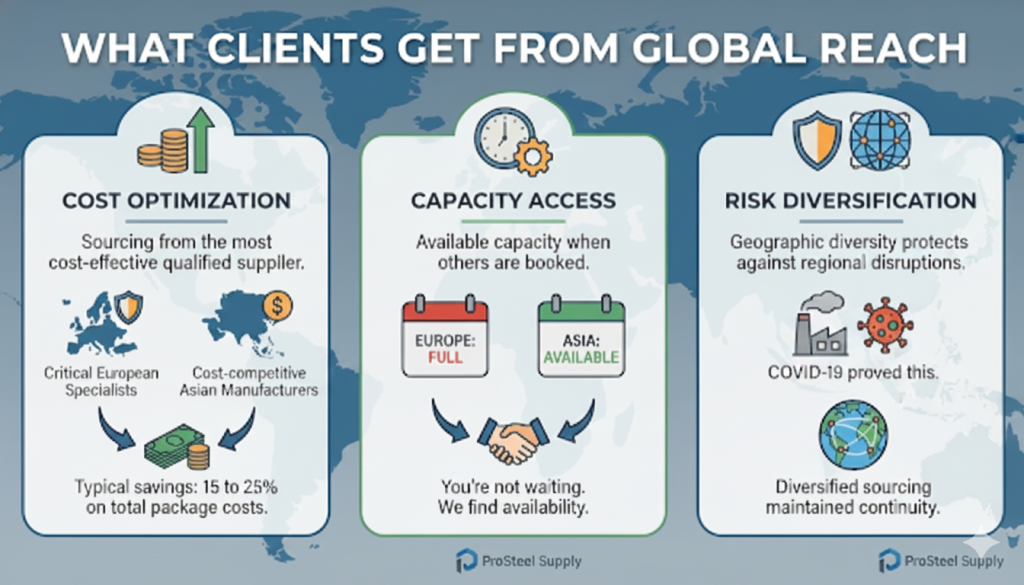

Combining European expertise with global reach delivers concrete benefits.

We source each component from the most cost-effective qualified supplier. Critical certified components from European specialists. Standard components from cost-competitive Asian manufacturers.

Typical savings: 15 to 25% on total forging package costs compared to all-European sourcing.

When European forges are fully booked, we have Asian capacity available. When Asian logistics create timeline risks, we have European alternatives.

You’re not waiting 12 months for forge capacity. We find availability.

Geographic diversity protects against regional disruptions. COVID-19 proved this. Clients with single-region supply chains faced major delays. Clients with diversified sourcing maintained continuity.

After 30 years building international forge relationships, we provide access you can’t build alone.

25+ qualified forges across Europe and Asia

Carbon steel to exotic nickel alloys

Small precision components to 12-meter diameter rings

NORSOK qualified to standard industrial grades

We visit forges quarterly. We track capacity. We maintain relationships. We verify quality. We coordinate inspections. We handle global logistics.

You get one contact point. We manage the complexity.

We match each requirement to the optimal forge. European when certification or complexity demands it. Asian when cost or capacity requires it. Always with quality verification and delivery assurance.

European expertise and global reach aren’t competing strategies. They’re complementary.

The best forging supply chain uses European quality standards and certification depth where needed, and global manufacturing capacity and cost efficiency where appropriate.

Yes, international sourcing requires more sophisticated supplier management. Yes, global logistics adds complexity. Yes, quality verification across continents demands systematic processes.

But the results justify the effort. Lower costs. Better capacity access. Risk diversification. Technical matching of forge to application.

The key is having the network and experience to execute it properly.

Need forgings that combine European quality with global efficiency? ProSteel Supply coordinates international sourcing daily. We’ll show you which forges match your specifications, what cost and lead time trade-offs exist, and how to structure procurement that optimizes your project outcomes.

Contact us for international sourcing guidance. Because the best solution isn’t always the closest forge.

Download our whitepaper and gain practical insights into materials, quality, and supply reliability.