Tight deadlines. Last-minute design changes. Sudden rush orders. Sound familiar? Maritime projects often involve months of specification discussions, only to expect delivery “yesterday.”

An installation vessel costing $100,000 to $800,000 per day can't wait for delayed deliveries. When specifications are finally established, rapid delivery of high-quality components becomes critical.

From ASME to Norsok - each geographic region has its own specific standards and preferences. The expertise to navigate these standards and find suppliers who can meet them has become increasingly rare.

Purchasing special installation tools in duplicate or triplicate as insurance against delays? With forged components weighing up to 4 tons each, spare parts represent a significant investment.

From LPG vessels in Australia to FPSOs with swivel stacks for oil production - maritime projects often require unique, non-standard solutions that fall outside normal production processes.

With 25+ years of experience in one of Europe’s oldest forging companies, we know exactly what happens behind the scenes when producing forged components. We understand the entire process – from material selection to heat treatment – and can therefore communicate realistically about what’s possible.

Whether you need forged rings up to 8.5 meters in diameter, special aluminum alloys from Mexico, or high-tech duplex steel grades – our network includes specialized producers worldwide who can meet specific standards and certifications.

We don’t take a “black box” approach. After placing an order, we create a follow-up schedule based on our experience. We check progress weekly and request clarification and photographic evidence if we sense any issues. We can dispatch inspection teams or visit the site ourselves to ensure everything stays on track.

We don’t make empty promises. If something goes wrong – and in this industry, challenges do arise – we inform you immediately so you can adapt your planning. We’d rather provide realistic timelines than pleasant surprises later.

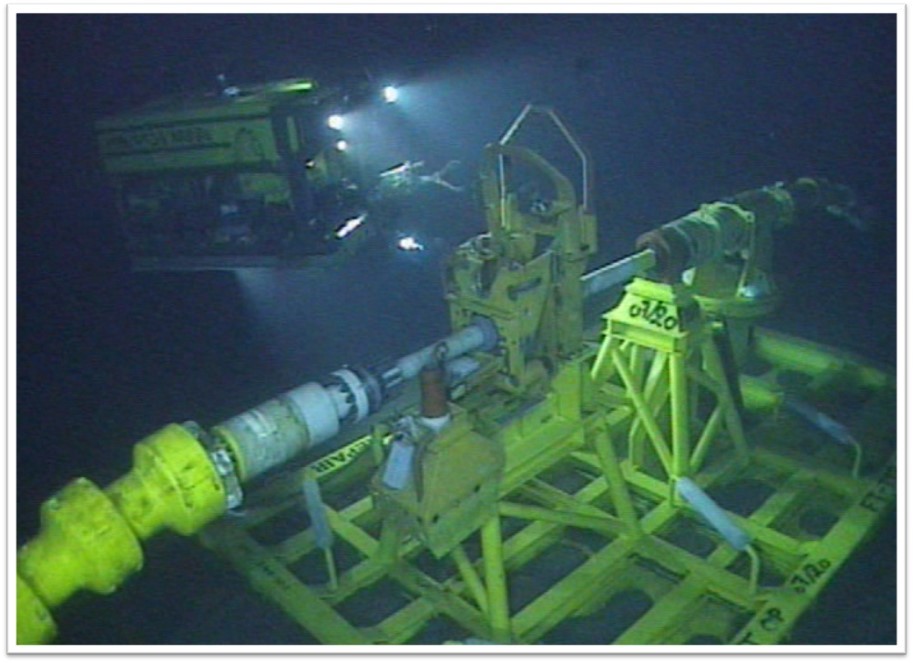

We've supplied specialized tools for hydrohammers used in monopile installation, with diameters between 3.5 and 6 meters. These tools often need to be made in duplicate or triplicate to ensure installation vessels worth hundreds of thousands per day don't experience downtime.

We've delivered 5.5-meter wide components weighing 4 tons each for LPG ships operating off Australia's coast. Our experience with swivel stacks and other critical components ensures your production vessels maintain operational efficiency.

When standard carbon steel won't suffice, we can source and process specialized materials like duplex and super duplex steels that withstand the corrosive offshore environment.

We provide specialized cladding solutions where corrosion resistance is critical but using solid specialty steel would be prohibitively expensive. By applying a high-grade metal layer to standard steel, we create cost-effective solutions that meet performance requirements.

With over 25 years in the maritime sector, we’ve seen projects evolve from 3-meter monopiles to today’s 8.5-meter giants. We’ve grown with the industry and understand its changing demands.

Installation ships, FPSOs, subsea equipment – we know how critical these components are and the costs of failure or delay. We’ve been working with some of our clients for over 25 years because we deliver not just products, but peace of mind.

From raw forged rings to fully machined, heat-treated, and coated components – we handle the entire process. By reducing your supply chain complexity, we also reduce your risk.

Contact us for a no-obligation consultation. We’ll analyze your requirements and provide realistic options that match your timeline and specifications.

Download our whitepaper and gain practical insights into materials, quality, and supply reliability.