“We need Lloyd’s to witness all testing. Non-negotiable.”

The email from the project engineer was direct.

The quote from the forge came back three days later. 40% higher than the standard price. Delivery pushed out by six weeks.

Welcome to offshore certification. A single checkbox on your specification sheet adds months to your timeline and tens of thousands to your budget.

After three decades coordinating marine equipment projects across global supply chains, we learned one truth: certifications don’t just verify quality. They dictate how projects run.

This article breaks down what class societies do, why ABS certification costs what it costs, what EN 10204 means, and how to navigate these requirements without destroying your schedule or budget.

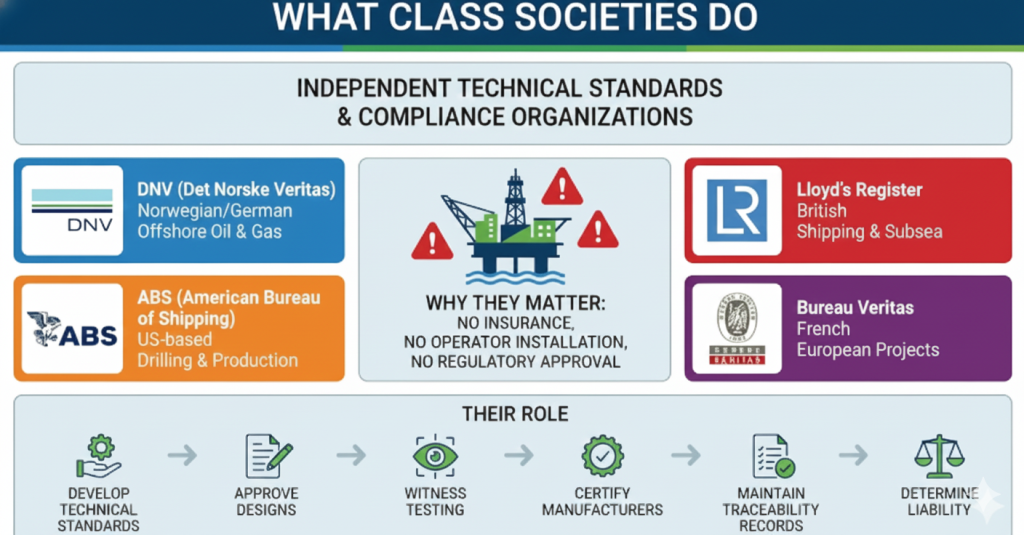

Class societies aren’t government agencies. They’re independent organizations that set technical standards and verify compliance for marine and offshore industries.

The major players:

Why they matter: When a production platform sits in 1,500 meters of North Sea water for 25 years, someone needs to verify that every component meets standards. Insurance companies won’t cover it. Operators won’t install it. Regulatory authorities won’t approve it.

That someone is the class society.

Their role extends beyond inspection. They develop technical standards, approve designs, witness testing, certify manufacturers, and maintain decades of traceability records. When something fails offshore, class society documentation determines liability.

EN 10204 defines four types of inspection documents for metallic products. Understanding these levels is essential for marine equipment procurement.

Manufacturer self-declares compliance. No independent verification. Your hardware store receipt.

Cost impact: Baseline (included in standard price)

Manufacturer’s authorized representative signs off. Includes test results: chemical composition, mechanical properties, heat treatment details. Standard for most forgings.

Cost impact: Minimal (0-5% premium)

Real-world note: 3.1 certificates are adequate for 90% of applications. The manufacturer has reputation and liability on the line. We’ve purchased thousands of forgings on 3.1 certificates without issues.

This is where class societies enter. An inspector from Lloyd’s, DNV, or ABS witnesses your testing. Physically present while tensile bars are pulled, impact specimens are broken, ultrasonic scans are performed.

Required for: Offshore certification requirements, pressure vessels, subsea equipment

Cost impact: Significant (10-25% premium, plus schedule impact)

The logistics challenge: That inspector must be scheduled, travel to the forge (possibly in another country), witness 2-3 days of testing, and issue documentation. Their calendar becomes your critical path.

Nuclear and aerospace only. Extreme cost (30-50%+ premium). Rare in oil and gas.

Let’s break down where money goes when you add ABS certification or DNV to your project.

Inspector Fees:

For a forge in Italy, expect an inspector from DNV Rotterdam to bill:

Additional Costs:

Standard duplex ring forging: €35,000 (with 3.1 certificate)

Same ring with DNV 3.2 certificate:

That’s a 41% increase. A realistic number we quote regularly.

Cost is visible. Schedule impact catches people off-guard.

Class society inspectors don’t sit idle waiting for your project. They’re scheduled weeks, sometimes months, in advance.

Real example: We had a project requiring Lloyd’s inspection in Germany. The forge completed the forging on schedule. The nearest available Lloyd’s inspector? Five weeks out. The client insisted on Lloyd’s specifically (their platform operator requirement). We waited five weeks.

Lesson learned: Book inspectors when you place the order, not when the forging is ready for testing.

With a 3.1 certificate, the forge tests when convenient.

With a 3.2 certificate, everything revolves around inspector schedule:

All on the same days.

One element slips, everything reschedules. That adds 2-4 weeks.

After witnessing tests, the inspector must prepare and issue certificates.

Your forging sits complete at the forge. Can’t ship. Waiting for paperwork.

Class society inspection isn’t a rubber stamp. They verify specific items.

Material traceability:

Mechanical testing:

Inspector witnesses test execution. Sample preparation, machine calibration, test performance, result recording. They don’t just review reports. They watch bars break.

Non-Destructive Testing:

Heat Treatment Verification:

This is critical. Improper heat treatment ruins corrosion resistance in stainless steels.

Not every forging needs a class society involved.

You NEED class certification (3.2) when:

You DON’T need class certification (3.1 is fine) when:

The conversation to have: When you receive a spec calling for 3.2 certificates, ask: “Is this required by the platform operator, or is it belt-and-suspenders?”

We’ve saved clients €100,000+ on projects by questioning blanket 3.2 requirements. Not every flange in a platform module needs independent inspection. Often only pressure-boundary items do.

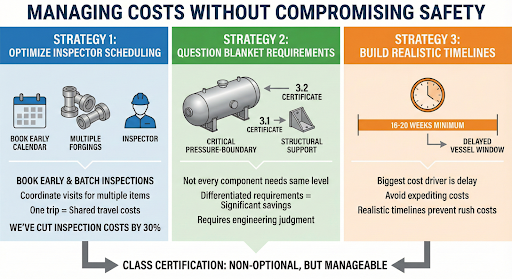

Class certification isn’t optional when required. But you can manage the cost.

Book inspectors early and batch inspections.

If you have multiple forgings from the same forge over 3-4 months, coordinate inspector visits to cover multiple items. One trip, three inspections, shared travel costs.

We’ve cut inspection costs by 30% through batching.

Not every component needs the same certification level.

This requires engineering judgment and client buy-in. But it’s how experienced operators manage costs.

The biggest cost driver is often delay. Missed vessel windows, idle fabrication yards, extended engineering teams.

Assume 16-20 weeks minimum for class-certified forgings. Trying to cut this to 12 weeks results in expediting costs that dwarf the certification premium.

After coordinating hundreds of certified forging projects, certain patterns signal trouble.

Unrealistic promises:

“We deliver DNV-certified duplex manifolds in 8 weeks.”

Reality: Material procurement alone takes 6-8 weeks for NORSOK duplex. Add forging, heat treatment, inspection, machining. You’re at 18-20 weeks minimum.

Vague certification claims:

“We’re certified by all major class societies.”

Reality: Certification is product-specific and time-limited. A forge has DNV approval for one product line but not others.

What to ask: “Show me your valid M-650 qualification certificate for 25Cr duplex forgings specifically.”

Missing documentation:

After delivery, certificates are incomplete or arrive months late.

Reality: Professional forges have documentation ready at shipment. It’s part of their system.

After 30 years in certified forging supply, we developed systems that save clients time and money.

Pre-Qualified Forge Network:

We work with forges holding current NORSOK M-650 qualifications and class society approvals. When you need DNV-certified superduplex, we know which three forges deliver. And which one has capacity next month.

Inspector Coordination:

We book class society inspectors when orders are placed, not when forgings are ready. Our relationships with society schedulers mean we get realistic availability information and secure earlier slots.

Documentation Management:

We maintain complete documentation archives. Test reports, certificates, traceability records. When you need paperwork years later for modifications or audits, we have it.

Realistic Timelines:

We won’t promise 12-week delivery on certified materials when we know it takes 18 weeks. Our reputation depends on meeting commitments. We quote conservative, deliver on time.

Class societies and material certification aren’t obstacles. They’re assurance that your marine equipment and offshore installations meet safety standards proven over decades.

Yes, EN 10204 3.2 certificates cost more. Yes, offshore certification adds weeks to schedules.

But these requirements exist because the consequences of failure are catastrophic. Environmentally, financially, and sometimes fatally.

The key is understanding what’s required versus what’s habit, and working with suppliers who’ve navigated these requirements hundreds of times.

Need forgings with class certification? ProSteel Supply handles DNV, Lloyd’s, ABS, Bureau Veritas, and NORSOK requirements daily. We’ll tell you what’s needed, what it costs, and how long it takes. Then deliver that.

Contact us for certification guidance on your next project. Because in offshore work, the paperwork matters as much as the product.

Download our whitepaper and gain practical insights into materials, quality, and supply reliability.