When your equipment will be submerged for 30 years at subsea depths, or processing corrosive fluids on an FPSO, material integrity isn’t just important – it’s everything. The oil and gas industry demands components that perform flawlessly under extreme conditions.

As "easy oil" becomes scarce, your equipment must function reliably in deeper waters, more corrosive conditions, and more remote locations. Finding suppliers with the expertise to deliver components for these environments is increasingly difficult.

From duplex and super duplex steels to specialized cladding solutions, oil and gas applications require materials that balance strength, corrosion resistance, and long-term reliability. Navigating these specifications requires specialized knowledge.

With Norsok, ASME, and other standards constantly evolving, maintaining compliance requires detailed understanding of certification processes. Many suppliers have allowed certifications to lapse during industry downturns, creating supply bottlenecks.

When planning refurbishment projects for aging installations, original drawings may be decades old with obsolete material specifications. Recreating these components with modern materials requires both historical knowledge and current expertise.

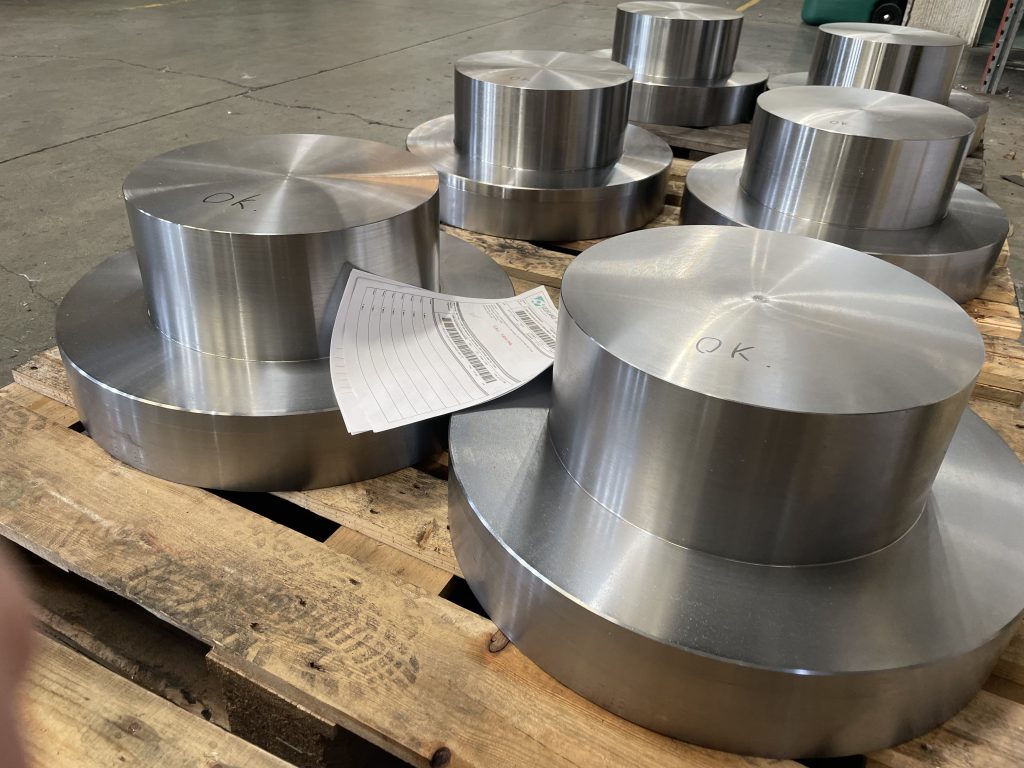

We provide specialized forged components for equipment designed to function reliably at depths of 1,000+ meters for decades without maintenance. Our experience with exotic alloys and extensive testing protocols ensures your subsea equipment performs in the harshest environments.

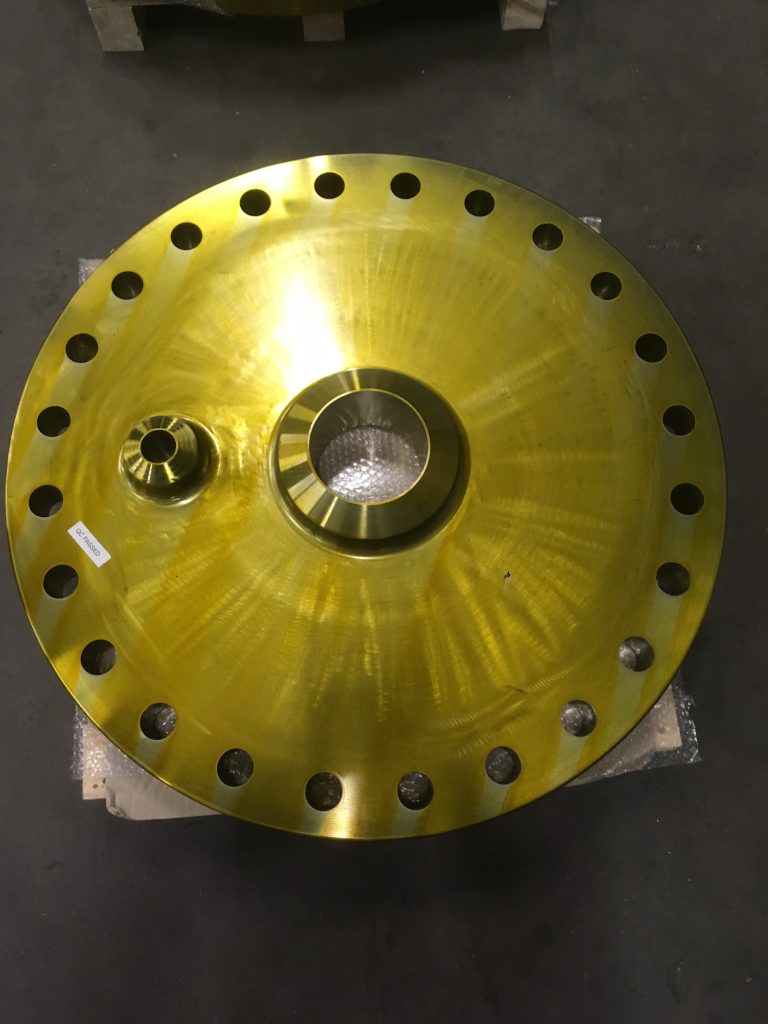

For floating production, storage and offloading vessels, we’ve supplied critical components for swivel stacks that handle the transfer of oil, gas, and control fluids while allowing the vessel to rotate with changing weather conditions.

We offer specialized cladding solutions where corrosion resistance is critical but using solid specialty steel would be prohibitively expensive. By applying high-grade alloy layers to standard steel bases, we create cost-effective solutions that meet performance requirements.

For older installations requiring replacement parts, we can work from vintage drawings to recreate components using modern materials and manufacturing techniques, often improving on the original designs while maintaining compatibility.

Our 25-year history in oil and gas projects means we've worked with the world's leading operators and equipment manufacturers. From North Sea developments to Australian LNG projects, we've supplied components throughout the industry's evolution.

We maintain relationships with leading metallurgists specializing in duplex and super duplex steels. When standard solutions don't fit your requirements, we can consult with these experts to develop custom approaches to material challenges.

We understand the importance of material qualification and testing. Our network includes specialized testing facilities that can perform the full range of mechanical, chemical, and corrosion testing required by the most demanding specifications.

Our established relationships with specialized manufacturing facilities across Europe, North America, and Asia allow us to match your requirements with the optimal producer for your specific components, ensuring both quality and cost efficiency.

For deepwater developments, we’ve supplied forged components with complex geometries and specialized material requirements, managing the entire process from initial forging through machining, heat treatment, and final certification.

We’ve delivered components for installations handling high H₂S content fluids, working with specialized steel producers to ensure materials meet the demanding requirements of sour service while maintaining mechanical properties.

For high-pressure connections requiring metal-to-metal sealing, we’ve supplied compact flanges manufactured to exacting tolerances, helping clients avoid costly mistakes when attempting to source or machine these specialized components themselves.

When critical components fail unexpectedly, our global network allows us to expedite production and delivery, reducing costly downtime for production facilities. While premium pricing applies for rush orders, we can significantly compress standard timelines when your operation is at stake.

Contact us for a no-obligation consultation. We’ll analyze your requirements and provide realistic options that match your timeline and specifications.

Download our whitepaper and gain practical insights into materials, quality, and supply reliability.