Capabilities

As a result of being active in the forging industry for many decades, the experienced staff of Prosteel Supply can provide you with the best suitable product from our qualified suppliers. Based on the required amount, dimensions, delivery time, mechanical specifications and test requirements, we know what producer will meet and exceed our customers demand.

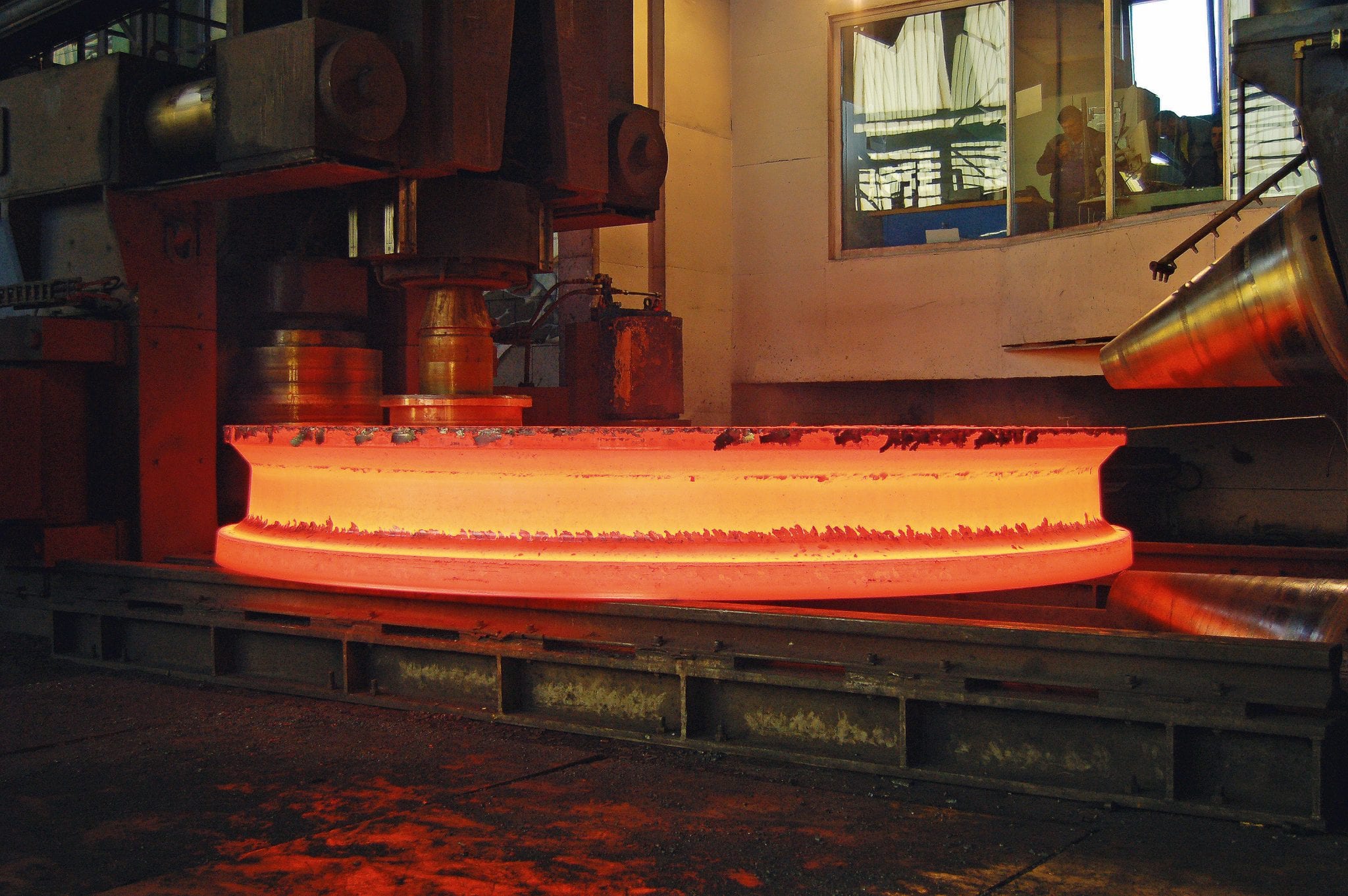

Ringrolling

Forged rings and bushings are the specialty of Prosteel Supply and we can provide you with a large variety of products, starting from outside diameters of 150 mm up to 7.800 mm.

Rough forged rings

These products are forged and heat treated according to specification, without and additional machining. Ideal for customers who need quality parts for further in-house machining. The average allowance on final dimensions is 10-30 mm and after steel blasting these parts are suitable for non-destructive testing.

Pre-machined rings

Rings and bushings forged, heat-treated and machined with an maximum allowance of 1-3 mm. on final dimensions. These parts are used by customers that want to do the final machining in-house or wanting to have the flexibility to make last-minute design adjustments to the products.

Complete machined rings

Steel rings or bushings that have been forged, heat-treated and machined / drilled to the customers drawing and other specifications. These parts are ready to be further assembled by the customer without any in-house machining. It is also possible to supply complete machined rings with cladding (overlay welding), surface treatment (hardening), coating (protective or decorative), etc.

Testing

Test certificates are evenly important as the forged products themselves to ensure our customers that they are getting exactly the products as ordered. Therefore, Prosteel Supply offers a complete range of test methods on all products required. Whether it is a basic 3.1 certificate or a third party inspection according to DNV or any other authority, we can provide exactly what is required.

Some of our testing methods at a glance:

- Hardness and tensile testing

- Ultrasonic testing

- Dye penetrant testing

- Magnetic particle testing

- Grain size testing

- PMI – Positive Material Identification

- Ferrite measurements

- Corrosion esting

- CTOD testing

Open-die forging

The most common supplied forged parts range between 200 kg. and 15 tons, however, Prosteel Supply can supply you with a large range and variety of forgings, in an almost unlimited range of materials. With forgings from just a few kilo’s up to forgings weighing 45 tons or more, we can supply whatever our customers desire.

Machining

Prosteel Supply can offer all forged parts machined as per customer specification. We are very familiar with machining specifications according to general classifications and to customer specific demands for e.g. the oil & gas industry and power industry.

- Turning

- Milling

- Drilling (deep-hole and regular)

- Polishing

- Design capabilities

Design capabilities

Prosteel Supply can offer full support in the design stage of a project or product, from material requirements to complete 3D FEA analysis and from cost optimization to development of engineered parts.

Some examples of engineering activities provided by our staff and in-house design tools:

- Flange calculation according to ASME regulations

- Design of Tees according to ASME regulations

- Swivel flange design, including 3D FEA analysis and design reports

- Design of transport frames

- Engineering support on material selection and qualification

- Production process optimization to improve material properties and

- reduce material and machining cost.

Questions about our products or anything else? call us!

Services

Contact

Tel: +31 (0)475 48 66 55

E-mail: info@prosteelsupply.com

V.A.T. nummer : NL003843622B01

K.v.K. register no. : 13032089

Bank : ING Roermond NL71INGB0677423462

Location

Sint Janskamp 15A

6101AG Echt (L)

The Netherlands